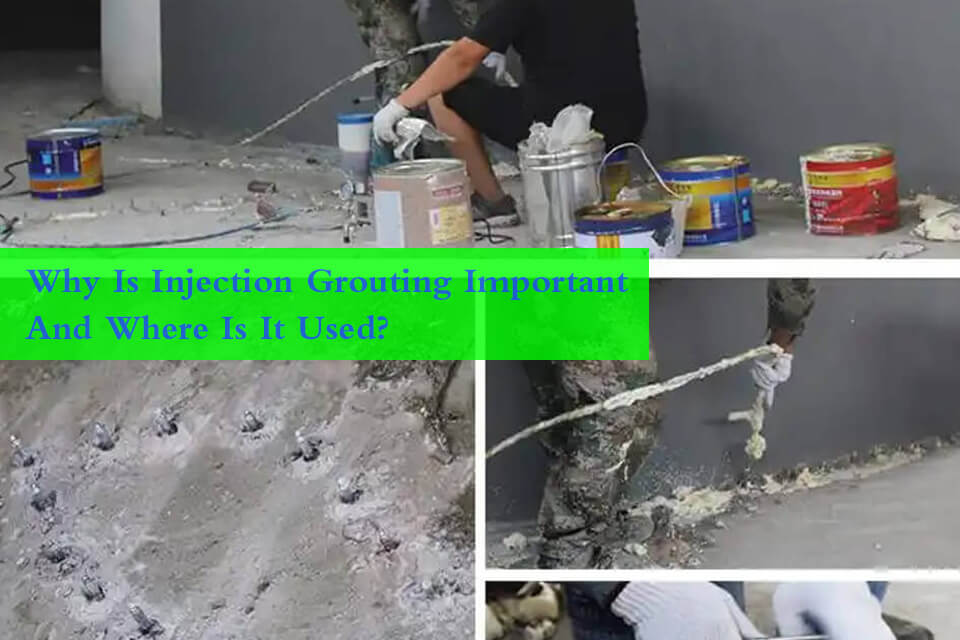

Mastering Concrete Crack Repair: Best Practices for Using Injection Packers

Concrete crack repair is a critical aspect of maintaining the structural integrity and longevity of buildings and infrastructure.

Unlocking the Secrets of Soil Stabilization: A Comprehensive Guide

Soil stabilization is a crucial process in construction and civil engineering that can make or break a project’s success.

Are There Different Size Grease Couplers? A Guide to Finding the Right Fit for Your Equipment

Grease couplers are essential tools in maintaining machinery and crack injection, ensuring that lubrication reaches all the critical parts that keep equipment running smoothly.