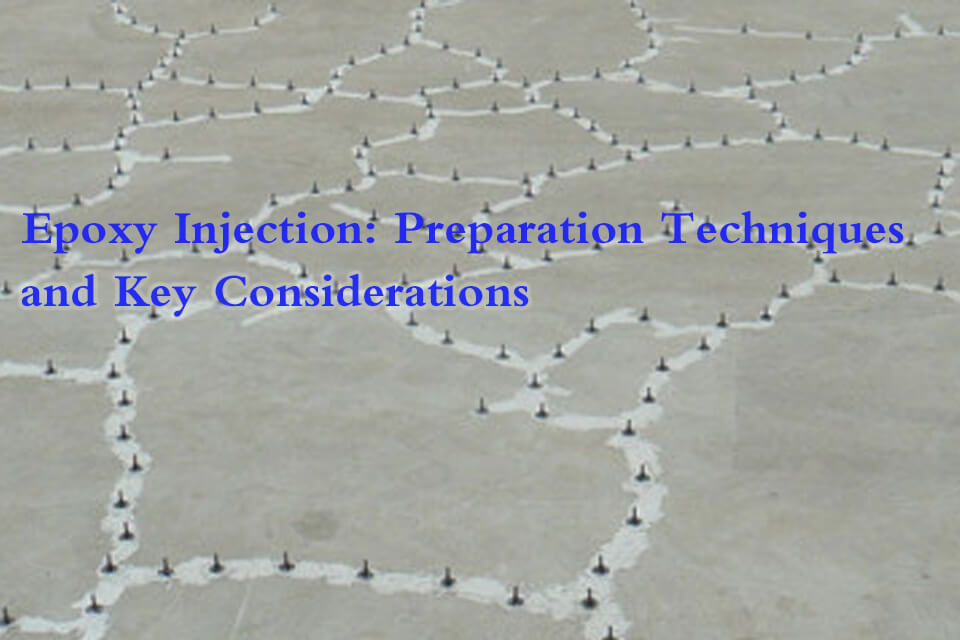

Epoxy Injection: Preparation Techniques and Key Considerations

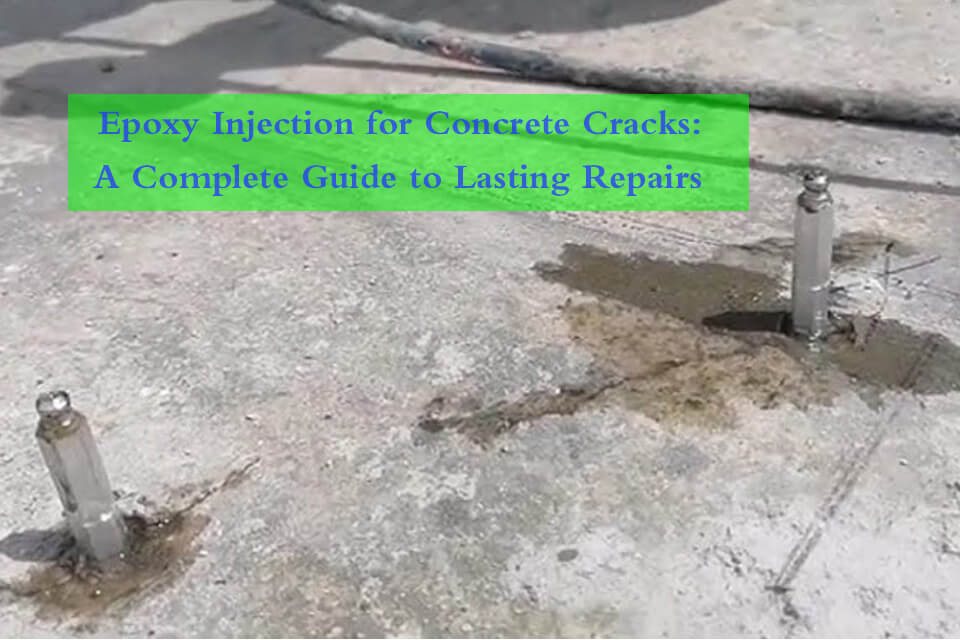

Epoxy injection is a sophisticated technique employed in the restoration of concrete structures by delivering a high-strength, low-viscosity epoxy resin into cracks.

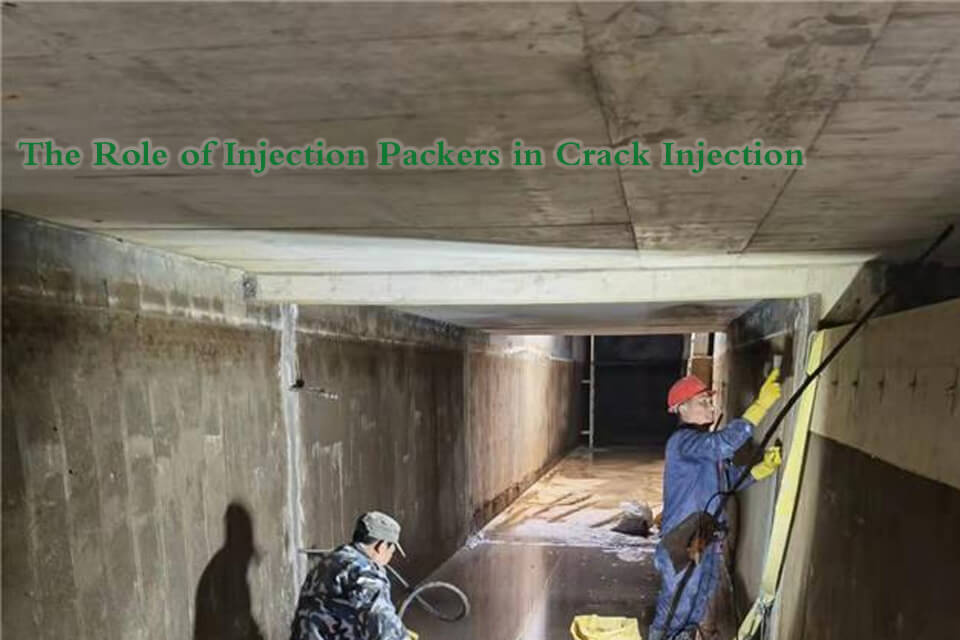

The Role of Injection Packers in Crack Injection and Structural Repair

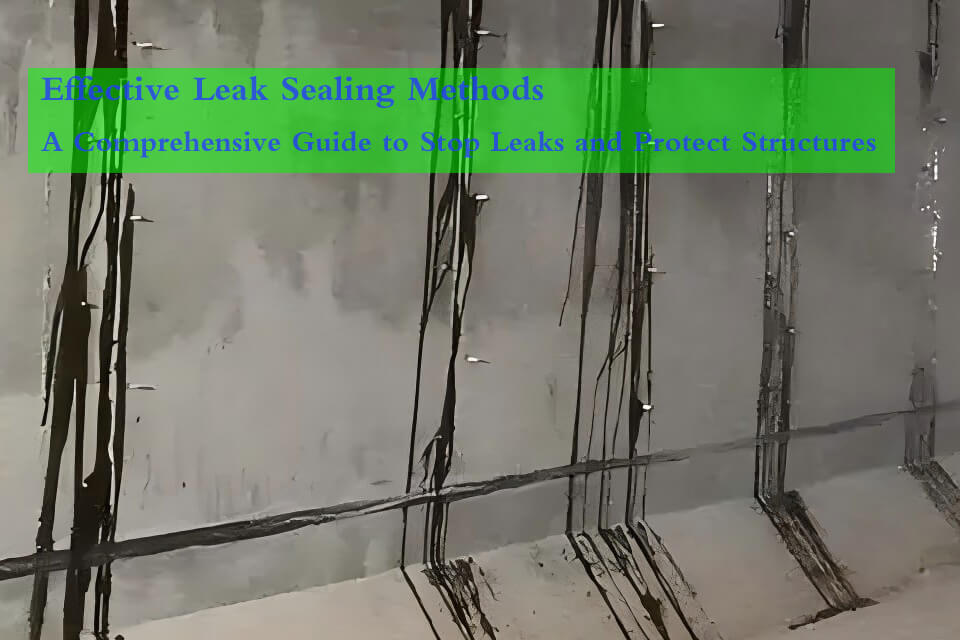

Crack injection is a critical method used in the restoration and strengthening of concrete structures. It involves injecting an adhesive chemical grout or resin into the cracks of a foundation, slab, or wall to seal and restore structural integrity.

Epoxy Injection vs. Polyurethane Injection: A Comparative Analysis for Structural Crack Repair

Epoxy injection and polyurethane injection are two widely used methods for repairing cracks in concrete structures, each distinguished by its unique chemical properties and applications.