How to Fix Foundation Cracks: Comprehensive Guide to Repairing Cracks in Your Concrete Foundation

Foundation cracks can be an alarming sight, but understanding how to address them can save you time, money, and worry.

Sealing Foundation Cracks: A Comprehensive Guide to Injection Packer Use

Foundation cracks are a homeowner’s nightmare, potentially leading to structural damage, water leaks, and costly repairs.

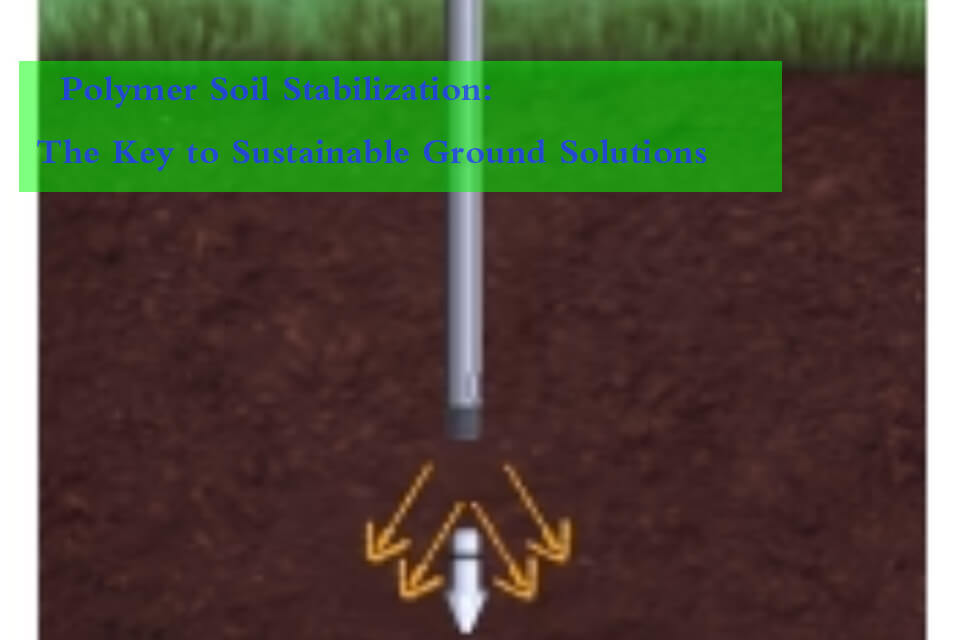

Polymer Soil Stabilization: The Key to Sustainable Ground Solutions

Soil stabilization is vital in construction and civil engineering, particularly for enhancing soil properties and ensuring durable infrastructure.