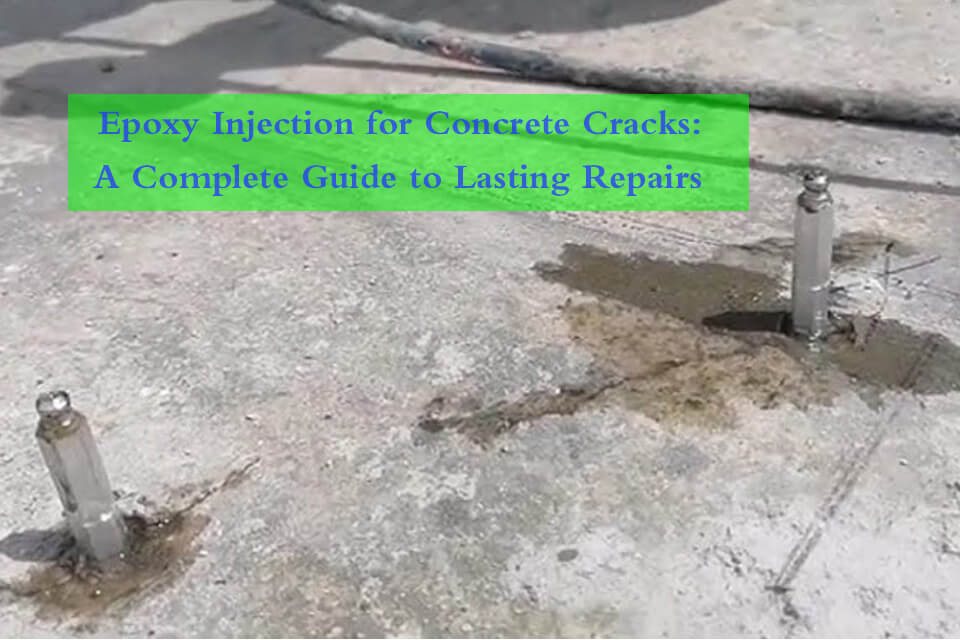

Polyurethane Foam Injection: The Ultimate Guide to Foundation Crack Repair

Are you dealing with pesky foundation cracks that just won’t go away? Look no further! This comprehensive guide will walk you through the innovative solution of polyurethane foam injection for crack repair.

Expert Guide: Tunnel Water Stop Injection – Advanced Solutions for Leak Repair

Are you dealing with water intrusion in your tunnel infrastructure? Water leakage in tunnels can lead to serious structural issues and operational disruptions.

Unveiling the Power of Heavy-Duty Electric Grout Pumps: Your Ultimate Guide

Have you ever wondered how large structures stay solid and intact? Grouting plays a key role!