How to Epoxy Injection Concrete Cracks: A Comprehensive Guide

Table of Contents

Summary

Understanding how to epoxy injection concrete cracks is essential for maintaining the integrity and longevity of your structures. This guide delves into effective epoxy injection techniques, offering valuable insights for both DIY enthusiasts and professionals.

Understanding Concrete Cracks

Epoxy injection is a specialized repair method used to seal and strengthen concrete cracks. This technique involves injecting a two-part epoxy resin into the cracks under pressure, filling the void and bonding the concrete back together. The process not only stops water leaks but also restores the structural integrity of the concrete

How Epoxy Injection Works

- Cleaning:The crack is thoroughly cleaned to remove debris and contaminants.

- Injection:Epoxy resin is injected into the crack using specialized equipment.

- Curing:The epoxy cures and hardens, sealing the crack and binding the concrete.

- Finishing:Any excess epoxy is removed, and the surface is smoothed for a seamless appearance.

Epoxy injection is favored for its durability, strong bonding properties, and ability to restore structural integrity.

Benefits of Epoxy Crack Injection

Epoxy crack injection offers numerous advantages over traditional repair methods:

- Strong Bonding:Epoxy forms a solid bond with concrete, enhancing its strength.

- Waterproofing:Seals cracks effectively, preventing water ingress.

- Longevity:Repairs last longer compared to other methods like sealants or fillers.

- Versatility:Suitable for various types of cracks, including vertical and horizontal.

- Aesthetic Appeal:Results in a smooth, seamless appearance without noticeable repairs.

These benefits make epoxy injection a preferred choice for both homeowners and professionals dealing with concrete repairs.

Identifying Foundation Cracks

Foundation cracks can be subtle or prominent, but recognizing them early can prevent more significant issues. Look for the following signs:

- Vertical Cracks:Often caused by foundation settling or shifting.

- Horizontal Cracks:Typically indicate substantial pressure from the soil or water.

- Diagonal Cracks:May result from movement or structural stress.

- Stair-Step Cracks:Common in brick or block foundations, following the mortar joints.

Regularly inspecting your foundation for these cracks can help in timely crack repair and avoid costly damages.

Preparing for Crack Repair

Proper preparation is essential for successful epoxy crack injection. Follow these steps to ensure the best results:

- Assessment:Evaluate the extent and severity of the cracks.

- Cleaning:Remove any loose debris, dirt, or vegetation from the cracks.

- Drying:Ensure the cracks are dry before applying epoxy to maximize adhesion.

- Accessibility:Make sure the crack is accessible for injection; use drills if necessary.

- Safety:Wear protective gear such as gloves and goggles during the repair process.

Adequate preparation enhances the effectiveness of epoxy injection and ensures a durable repair.

Step-by-Step Epoxy Injection Process

- Cleaning the Crack

Begin by thoroughly cleaning the crack to remove any loose particles, dirt, or debris. Use a wire brush or compressed air to ensure the crack is free of obstructions, allowing the epoxy to penetrate effectively.

- Drilling Injection Ports

For deeper cracks, drill small holes at intervals along the crack. These ports facilitate the injection of epoxy resin into the voids, ensuring comprehensive coverage and sealing.

- Mixing Epoxy Resin

Prepare the epoxy resin according to the manufacturer’s instructions. Accurate mixing is crucial for the resin to cure properly and form a strong bond with the concrete.

- Injecting the Epoxy

Using a specialized injection kit, inject the epoxy resin into the crack under pressure. Start from the lowest point and work upwards, allowing the resin to fill the entire crack and any voids.

- Curing and Finishing

Allow the epoxy to cure as per the recommended time. Once hardened, remove any excess epoxy and smooth the surface for a clean, finished look.

Following these steps ensures a robust and lasting repair of concrete cracks

Choosing the Right Epoxy Resin

Selecting the appropriate epoxy resin is crucial for effective crack repair. Consider the following factors:

- Viscosity:Thicker resins are suitable for filling large cracks, while thinner ones are ideal for narrow fissures.

- Curing Time:Depending on your project timeline, choose a resin with an appropriate curing duration.

- Strength:Ensure the resin offers sufficient strength to reinforce the concrete structure.

- Compatibility:The epoxy should be compatible with the existing concrete materials.

Researching and selecting the right epoxy resin can significantly impact the success of your crack injection repair.

DIY Foundation Crack Repair Tips

For those inclined to tackle foundation crack repairs themselves, here are some valuable tips:

- Gather Necessary Tools:Ensure you have all required tools, including an injection kit, epoxy resin, drills, and safety gear.

- Follow Instructions:Carefully adhere to the manufacturer’s guidelines for mixing and applying the epoxy.

- Work in Sections:Divide the crack into manageable sections to ensure thorough injection and curing.

- Monitor Progress:Regularly check the injection process to prevent overfilling or uneven application.

- Safety First:Always prioritize safety by wearing appropriate protective equipment and working in a well-ventilated area.

By following these tips, DIY enthusiasts can achieve professional-quality results in foundation crack repair.

When to Seek Professional Help

While DIY repair is feasible for minor cracks, certain situations necessitate professional intervention:

- Extensive Damage:Large or multiple cracks may require expert assessment and repair.

- Structural Concerns:If cracks indicate significant structural issues, professionals can provide comprehensive solutions.

- Specialized Techniques:Complex repairs, such as epoxy injection in hard-to-reach areas, benefit from professional expertise.

- Time Constraints:Professionals can complete repairs efficiently, minimizing downtime and potential further damage.

Recognizing when to seek professional help ensures that foundation cracks are addressed effectively and safely.

Maintaining Repaired Concrete

Proper maintenance is essential to preserve the integrity of repaired concrete. Follow these practices:

- Regular Inspections:Periodically check for new cracks or signs of wear.

- Seal Coating:Apply sealants to protect against moisture infiltration and environmental damage.

- Proper Drainage:Ensure adequate drainage around the foundation to prevent water accumulation.

- Load Management:Avoid placing excessive weight on repaired areas to maintain their strength.

- Immediate Repairs:Address any new cracks promptly to prevent escalation.

Consistent maintenance extends the lifespan of concrete repairs and safeguards your structure from future issues.

Common Mistakes to Avoid

Avoiding common mistakes can enhance the effectiveness of epoxy injection repairs:

- Inadequate Cleaning:Failing to properly clean the crack can hinder epoxy adhesion.

- Incorrect Mixing:Improperly mixed epoxy can result in weak bonds and incomplete curing.

- Overfilling:Excessive epoxy can lead to surface discoloration and uneven finishes.

- Ignoring Safety Precautions:Neglecting safety measures can result in accidents and health risks.

- Using Inappropriate Epoxy:Selecting the wrong type of epoxy can compromise the repair’s durability.

Being aware of these mistakes ensures a successful and long-lasting concrete crack repair.

Epoxy Injection vs. Other Repair Methods

Epoxy injection stands out among various concrete repair methods due to its unique advantages:

**Repair Method Benefits Limitations **Epoxy Injection Strong bonding, waterproof, long-lasting Requires proper preparation and skill Sealants Easy application, cost-effective Less durable, may require frequent reapplication Polyurethane Foam Flexible, great for active water leaks Not as strong as epoxy, may degrade over time Hydraulic Cement Quick setting, effective for active leaks Can be brittle, limited to small cracks

Why Choose Epoxy Injection?

Epoxy injection offers a superior combination of strength, durability, and waterproofing, making it an ideal choice for serious concrete crack repairs. Unlike temporary fixes like sealants, epoxy provides a permanent solution that reinforces the concrete and prevents future damage.

Frequently Asked Questions

- How long does epoxy injection take to cure?

- Epoxy injection typically cures within 24 hours, but full strength may take up to a week depending on environmental conditions.

- Can epoxy injection be used for all types of cracks?

- Epoxy is best suited for non-moving cracks. For actively moving cracks, flexible materials like polyurethane may be more appropriate.

- Is epoxy injection waterproof?

- Yes, epoxy injection creates a waterproof seal that prevents water ingress and protects the concrete from further damage.

- Can I perform epoxy injection myself?

- While DIY epoxy injection is possible for minor cracks, larger or more complex repairs are best handled by professionals to ensure effectiveness and safety.

- How much does epoxy injection repair cost?

- Costs vary based on crack size, accessibility, and the extent of damage. On average, epoxy injection can range from $300 to $700 per crack.

Conclusion

Epoxy injection is a highly effective method for repairing concrete cracks, offering durability, strength, and waterproofing. Whether you’re a DIY enthusiast or seeking professional repair services, understanding the process and best practices ensures a successful outcome. By addressing foundation cracks promptly and maintaining repaired concrete, you can safeguard your structures against future damage.

Key Takeaways

- Identify Cracks Early:Regular inspections help detect cracks before they worsen.

- Choose the Right Epoxy:Selecting appropriate epoxy resin is crucial for effective repairs.

- Proper Preparation:Clean and prepare cracks thoroughly for optimal epoxy adhesion.

- Follow Step-by-Step Process:Adhering to the epoxy injection steps ensures a durable repair.

- Maintain Repaired Areas:Ongoing maintenance preserves the integrity of concrete structures.

Comments

The Advantages of Chemical Grouting: Strengthening Structures for a Safer Future

Chemical grouting is a powerful and versatile solution for strengthening soil, sealing leaks, and stabilizing foundations in challenging construction environments.

How Injection Packers Enhance the Dam Structures Impermeability

Keeping a dam waterproof is essential for maintaining its structural integrity and preventing water erosion.

Understanding Grouting Packers: Essential Tools for Effective Injection Grouting

Injection packers play a vital role in the grouting process, enabling precise injection of grouting materials into cracks, joints, and voids within structures.

Epoxy Injection for Concrete Cracks: The Ultimate Guide to Effective Crack Repair

Concrete cracks can jeopardize the integrity of any structure, from foundations to walls, but epoxy injection offers a powerful solution for repairing and sealing these cracks.

How to Fix Foundation Cracks: Comprehensive Guide to Repairing Cracks in Your Concrete Foundation

Foundation cracks can be an alarming sight, but understanding how to address them can save you time, money, and worry.

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

Effective Crack Injection for Concrete Repair: Step-by-Step Guide

Concrete cracks are a common issue in many structures, often leading to leaks that can cause significant damage if not properly sealed. Crack injection is a highly effective technique for repairing these cracks and stopping water infiltration.

Unlocking the Secrets of Soil Stabilization: A Comprehensive Guide

Soil stabilization is a crucial process in construction and civil engineering that can make or break a project’s success.

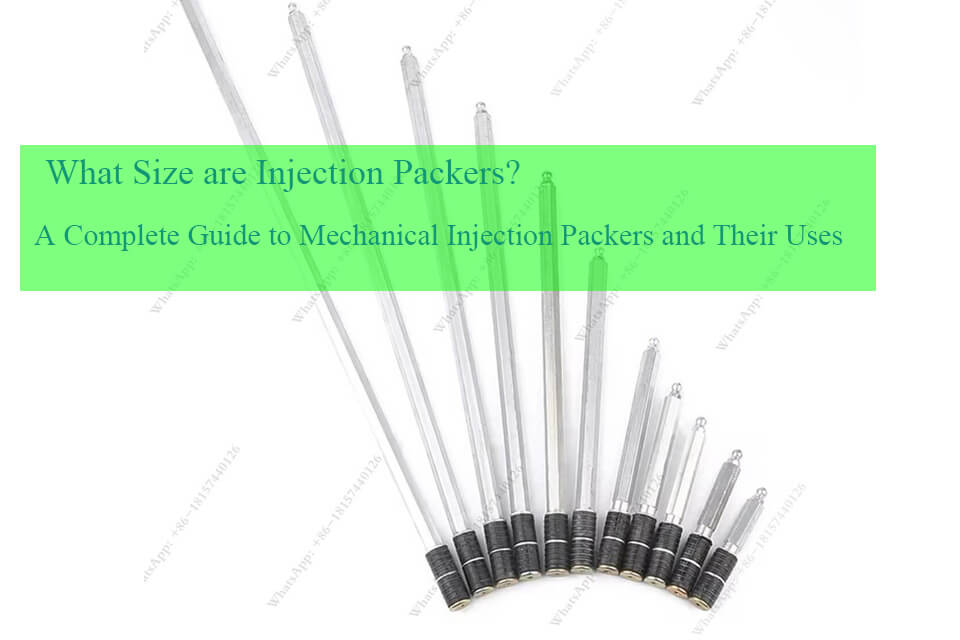

What Size are Injection Packers? A Complete Guide to Mechanical Injection Packers and Their Uses

When it comes to crack injection and waterproofing, the size and type of mechanical injection packers you use can make all the difference.