How to Fix Foundation Cracks: Comprehensive Guide to Repairing Cracks in Your Concrete Foundation

Foundation cracks can be an alarming sight, but understanding how to address them can save you time, money, and worry.

Key Benefits of Using Injection Packers for Concrete Repair

Injection packers are an essential tool for addressing cracks and structural deficiencies in concrete. These devices allow for precise application of repair materials

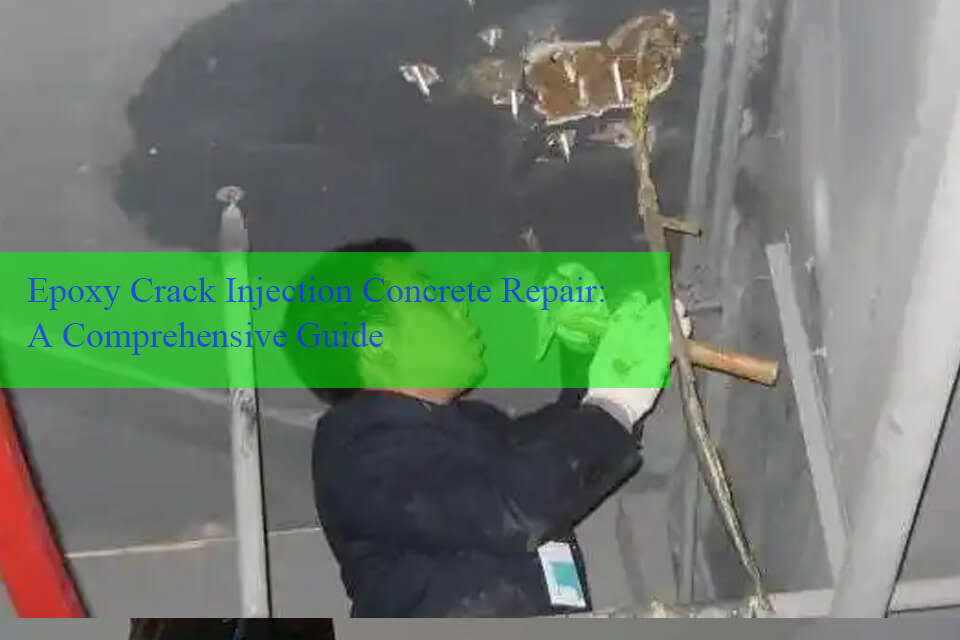

Comprehensive Guide of Epoxy Crack Injection Concrete Repair

Epoxy crack injection is a reliable and scientifically advanced method for repairing concrete structures, particularly those suffering from cracks.