A Complete Guide to Chemical Injection Lances for Deep Grouting

Table of Contents

Chemical Injection Lances for Deep Grouting

Unlike standard injection packers, which are suitable for shorter depths (5 cm to 100 cm), injection lances can reach significantly deeper areas, typically starting from 1m to 5 m or more. With their Seamless body and high-pressure durability, chemical injection lances ensure efficiency, strength, and reliability in demanding injection environments. In this article, we will explore the features, specifications, advantages, and applications of chemical injection lances.

What Are Chemical Injection Lances?

Chemical injection lances are extended injection packers designed for deep chemical grouting. Their primary role is to deliver grouting materials, such as polyurethane or acrylic gel, into hard-to-reach underground gaps.

Key Components of an Injection Lance

Separated Tip: Ensures easy insertion into drill holes without breakage.

Seamless Pipe Body: Provides durability and can withstand high-pressure environments.

Button Head Grease Nipple : Connects the lance securely, allowing smooth material flow.

The lance’s high mechanical performance and corrosion resistance make it ideal for both low-pressure and high-pressure chemical grouting projects.

Specifications of Chemical Injection Lances

The primary material used for injection lances is hardened alloys, known for its strength, toughness, and excellent mechanical properties. Below is the detailed composition of the steel used in the lance body:

| Property | Specification |

| Yield Strength | ≥ 355 MPa |

| Tensile Strength | 470 – 630 MPa |

| Chemical Composition | |

| Carbon (C) | ≤ 0.20% |

| Manganese (Mn) | ≤ 1.60% |

| Silicon (Si) | ≤ 0.55% |

| Phosphorus (P) | ≤ 0.035% |

| Sulfur (S) | ≤ 0.035% |

| Key Features | |

| High Strength | Excellent tensile and yield strength |

| Weldability | Good weld ability without preheating |

| Machinability | Easily machinable |

| Applications | |

| Structural Components | Bridges, buildings, steel frames |

| Mechanical Manufacturing | Heavy machinery, hydraulic cylinders |

| Pipes and Profiles | Seamless pipes, square tubes |

| Automotive and Shipbuilding | Vehicle frames, ship structures |

Grease Head Options

Injection lances come with a variety of grease heads for better compatibility and performance. Available specifications include: M13*1.0, G 1/4’’ M18*1.5

The grease head options ensure flexible connections and smooth flow of grouting materials.

Features and Advantages of Chemical Injection Lances

Chemical injection lances are designed for superior performance in deep grouting projects. Their unique features and benefits include:

Easy Insertion: The separated tip allows effortless penetration into drill holes, reducing manpower and preventing breakage.

Variable Lengths: Available in various lengths and diameters, injection lances can penetrate deep soils, concrete cracks, or cavities as needed. Male and female joint connections enable the lances to reach longer and deeper depths, making them ideal for extended grouting needs.

Optimized Flow: The lance connection head includes a large ball design that promotes efficient flow of chemical grouting materials.

Corrosion Resistance: The inclusion of chromium elements in the pipe body enhances corrosion resistance, ensuring the lance can inject various materials, including: Hydrophobic polyurethane, Hydrophilic PU, Acrylic gel etc.

With these features, injection lances deliver reliability and efficiency across a range of demanding applications.

Chemical Injection Lance Sizes and Supplying Range

Injection lances are available in multiple sizes to meet the needs of different grouting depths and pressures. Below are the commonly supplied sizes:

| Size | Length | Diameter |

| 13*500mm | 0.5 meter | 13mm |

| 13*1000mm | 1 meters | 13mm |

| 18*500mm | 0.5 meter | 18mm |

| 18*1000mm | 1 meter | 18mm |

| 21.3*500mm | 0.5meters | 21.3mm |

| 21.3*1000mm | 1 meter | 21.3mm |

Additionally, with a coupling (connector) , injection lances can extend up to 5 meters or more depth for deeper grouting projects.

Applications of Chemical Injection Lances

Chemical injection lances are primarily used for soil stabilization and underground structure reinforcement. The high-pressure ram impact of the lance allows chemical grouting materials to penetrate small gaps and stabilize the soil effectively. Key applications include:

Soil stabilization for construction foundations

Sealing underground cracks

Strengthening tunnels, bridges, and underground structures

Deep ground injection to control water seepage

The durability and versatility of chemical injection lances make them essential for large-scale and demanding construction projects.

Conclusion

Chemical injection lances are a powerful and reliable solution for deep grouting applications. With their seamless body, high-pressure resistance, and optimized flow design, they offer unparalleled performance for underground stabilization and chemical injection projects. Available in a variety of sizes and specifications, chemical injection lances meet the needs of diverse grouting environments, ensuring long-lasting stability and efficiency. For any project requiring deep chemical grouting, chemical injection lances are the ideal choice for achieving outstanding results.

Comments

The Role of Injection Packers in Crack Injection and Structural Repair

Crack injection is a critical method used in the restoration and strengthening of concrete structures. It involves injecting an adhesive chemical grout or resin into the cracks of a foundation, slab, or wall to seal and restore structural integrity.

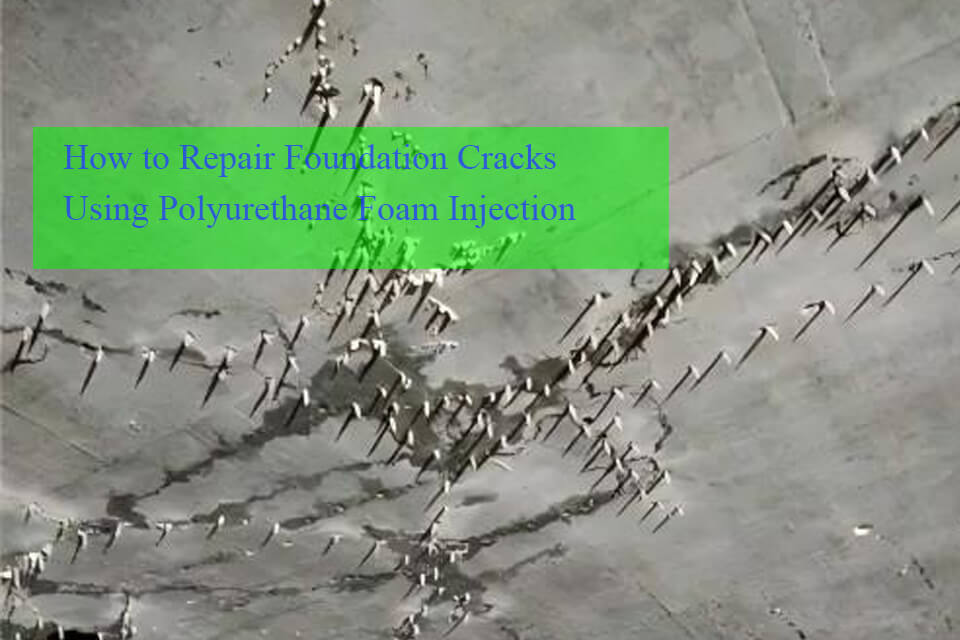

How to Repair Foundation Cracks Using Polyurethane Foam Injection

Foundation cracks can lead to serious structural issues if left unaddressed.

Unveiling the Power of Heavy-Duty Electric Grout Pumps: Your Ultimate Guide

Have you ever wondered how large structures stay solid and intact? Grouting plays a key role!

How to Fix Foundation Cracks: Comprehensive Guide to Repairing Cracks in Your Concrete Foundation

Foundation cracks can be an alarming sight, but understanding how to address them can save you time, money, and worry.

Injection Lances for Soil Stabilization: A Technical Overview

Injection lances are essential tools for soil stabilization and ground reinforcement, designed to improve the structural integrity of the soil by injecting stabilizing agents at precise depths.

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

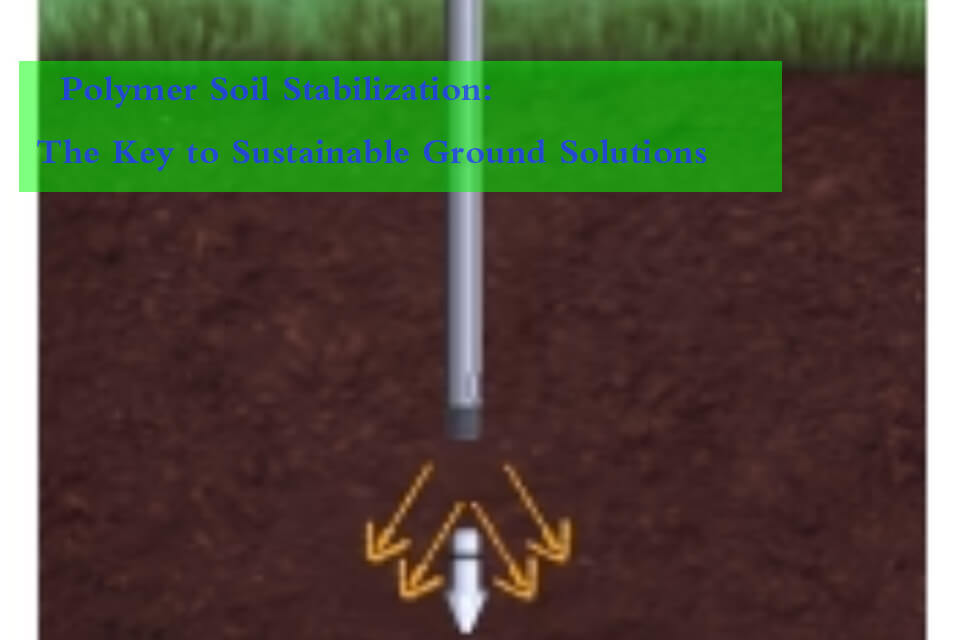

Polymer Soil Stabilization: The Key to Sustainable Ground Solutions

Soil stabilization is vital in construction and civil engineering, particularly for enhancing soil properties and ensuring durable infrastructure.

How to Fix Foundation Cracks: A Comprehensive Guide

Foundation cracks can jeopardize the structural integrity of any building, posing a risk to both property and safety.

Understanding Grouting Packers: Essential Tools for Effective Injection Grouting

Injection packers play a vital role in the grouting process, enabling precise injection of grouting materials into cracks, joints, and voids within structures.