Injection Lances for Soil Stabilization: A Technical Overview

Injection lances are essential tools for soil stabilization and ground reinforcement, designed to improve the structural integrity of the soil by injecting stabilizing agents at precise depths.

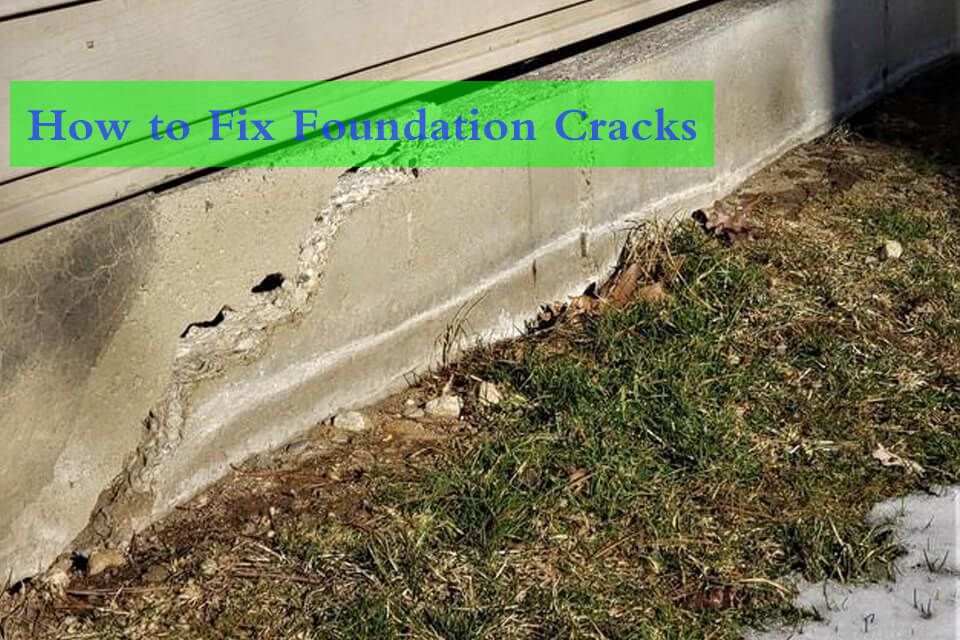

How to Fix Foundation Cracks: Comprehensive Guide to Repairing Cracks in Your Concrete Foundation

Foundation cracks can be an alarming sight, but understanding how to address them can save you time, money, and worry.

Button Head Grease Fittings: Essential for Construction, Heavy-Duty, and Waterproof Industry Applications

In the world of heavy machinery maintenance, ensuring smooth operation and longevity is essential. One key component that helps achieve this is the button head grease fittings,