The Power of PU Injection: Effective Waterproofing for Cracks and Leaks

Table of Contents

The Power of PU Injection

By filling voids and sealing cracks with polyurethane resin, PU injection effectively stops water infiltration and strengthens structures. This guide explores PU injection grouting, its applications, and the key advantages that make it a trusted solution in the waterproofing industry.

Water leakage can severely damage structures, leading to costly repairs. This article provides an in-depth look at PU injection waterproofing so you can understand if it’s the right solution for your needs. By explaining the benefits, process, and applications of PU injection, this guide offers valuable insights into its role in waterproofing systems

What Is PU Injection, and How Does It Work?

PU injection (Polyurethane Injection) is a grouting method used to waterproof cracks and voids in concrete. The technique involves injecting polyurethane resin into cracks or joints, where it reacts with water to form a flexible, durable seal. The resin expands upon contact with moisture, effectively filling gaps and creating a waterproof barrier.

Polyurethane injection is especially useful for areas prone to leakage or structural weaknesses, as it not only stops water from entering but also strengthens the affected areas.

Why Choose Polyurethane Injection for Waterproofing?

Polyurethane injection has become a popular choice for waterproofing due to its versatility and effectiveness. Unlike traditional waterproofing methods that might require extensive hacking or surface work, PU injection is minimally invasive, making it ideal for applications where access is limited or disruption must be minimized.

PU injection grouting can be applied to various structures, including basements, tunnels, parking structures, and retaining walls. Its ability to seal cracks while remaining flexible under structural movement adds significant value to its waterproofing properties.

How Does PU Injection Grouting Solve Water Leakage Problems?

Water leakage in concrete can lead to structural deterioration and costly repairs. PU injection addresses this by injecting resin into cracks where it expands to form a waterproof seal. As a result, PU injection grouting provides an effective, long-term solution for preventing water ingress and maintaining structural integrity.

Once the resin cures, it creates a water-resistant barrier that blocks leaks even in high-pressure environments. This makes PU injection an ideal solution for waterproofing systems in underground or high-moisture locations.

The Key Advantages of PU Injection Waterproofing

Some of the key advantages of PU injection include:

- Fast and Flexible Application: Can be applied to various surfaces with minimal preparation.

- Permanent Waterproofing: Forms a durable, water-resistant barrier that lasts.

- Cost-Effective: Offers a reliable alternative to more invasive waterproofing methods.

In addition, the flexibility of polyurethane resin means that the PU injection process can accommodate slight movements within the structure, ensuring the waterproofing remains intact over time.

Types of Polyurethane Injection: Resin vs. Foam

Polyurethane injection comes in two primary types: resin and foam. Each serves different waterproofing purposes based on the specific requirements of the job:

- Polyurethane Resin: Best for narrow cracks, as it provides a solid seal without significant expansion.

- Polyurethane Foam: Expands upon contact with water, making it ideal for larger cracks or voids.

Both types of PU injection offer high water resistance and durability, but choosing the right one depends on the extent of the cracks and the intended application.

How Does PU Injection Repair Cracks in Concrete?

Concrete cracks occur for various reasons, including settling, structural stress, and thermal expansion. PU injection repairs these cracks by filling and sealing them with polyurethane resin. Once injected, the resin bonds with the concrete, forming a waterproof and flexible seal.

PU injection is highly effective for concrete crack repair because it not only stops water infiltration but also restores structural stability. This method works well for vertical and horizontal cracks, providing a reliable and long-lasting repair solution.

Understanding PU Injection Cure Time

Cure time for PU injection can vary depending on environmental factors such as temperature, humidity, and crack size. Generally, PU injection takes several hours to fully cure, though some fast-reacting polyurethanes can set within minutes in emergency situations.

To ensure effective results, it’s crucial to allow adequate curing time. Working with waterproofing experts can help determine the right resin type and cure time based on your project’s unique needs.

Is PU Injection Effective for Void Filling?

Yes, PU injection is effective for void filling, especially in situations where water intrusion is a concern. The expansion of polyurethane foam allows it to fill large voids and stabilize loose soil around foundations, enhancing the structure’s load-bearing capacity and preventing future settlement issues.

This application makes PU injection ideal for infrastructure projects like tunnels and foundations, where voids need to be addressed to maintain stability and prevent further damage.

How to Choose a PU Injection Waterproofing Expert

Finding the right PU injection expert is essential to ensure a successful waterproofing project. When selecting a provider, consider factors like experience, equipment, and reviews. A qualified waterproofing expert should offer guidance on the best type of PU injection and provide a comprehensive waterproofing system solution tailored to your structure’s needs.

It’s also beneficial to request references and review past projects to verify their expertise in polyurethane injection for waterproofing.

Conclusion: The Benefits of PU Injection for Long-Lasting Waterproofing

PU injection is a powerful and cost-effective solution for waterproofing and crack repair. From concrete crack repair to void filling, PU injection grouting offers a versatile approach to maintaining structural integrity in various environments.

With its flexible application, minimal disruption, and durable results, PU injection has proven itself as a leading choice in modern waterproofing solutions.

Conclusion: Key Takeaways on PU Injection for Waterproofing

- Effective Waterproofing: PU injection creates a durable, water-resistant barrier in concrete structures.

- Minimal Invasion: Requires no extensive surface preparation, making it ideal for confined spaces.

- Flexible and Durable: Adapts to structural movement and offers long-lasting protection.

- Suitable for Various Applications: Works for cracks, void filling, and water leakage control.

- Professional Expertise Recommended: Consulting with waterproofing experts ensures optimal results.

For more information or assistance with PU injection waterproofing, feel free to reach out to industry professionals

Comments

The Advantages of Chemical Grouting: Strengthening Structures for a Safer Future

Chemical grouting is a powerful and versatile solution for strengthening soil, sealing leaks, and stabilizing foundations in challenging construction environments.

What Is Injection Packer

Injection packers are vital tools in both construction and maintenance sectors, designed to address critical issues related to sealing and waterproofing.

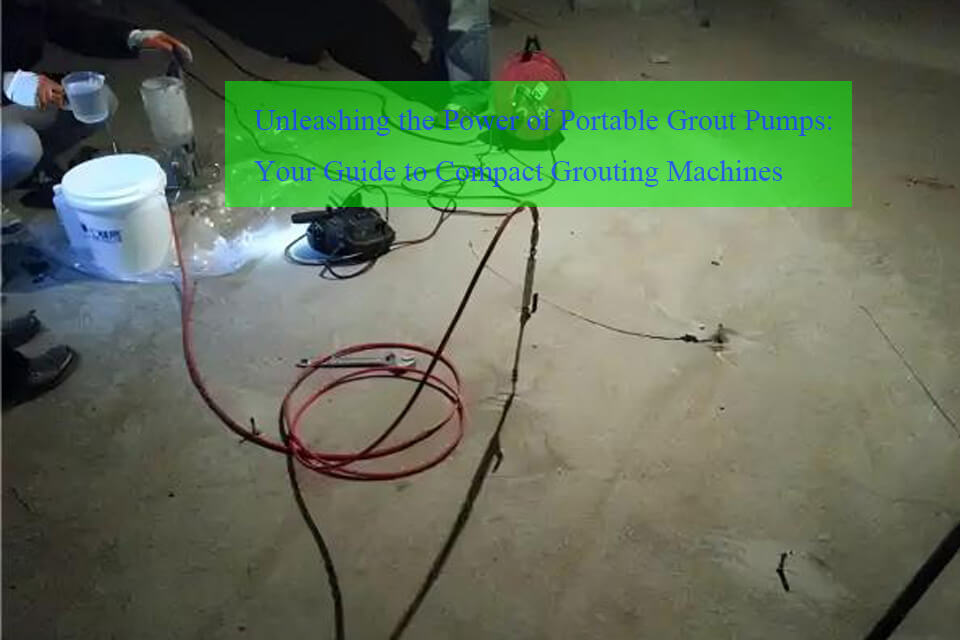

Unleashing the Power of Portable Grout Pumps: Your Guide to Compact Grouting Machines

Looking to tackle a construction project that involves grouting but worried about heavy equipment? Discover how portable grout pumps can revolutionize your work!

Injection Lances for Soil Stabilization: A Technical Overview

Injection lances are essential tools for soil stabilization and ground reinforcement, designed to improve the structural integrity of the soil by injecting stabilizing agents at precise depths.

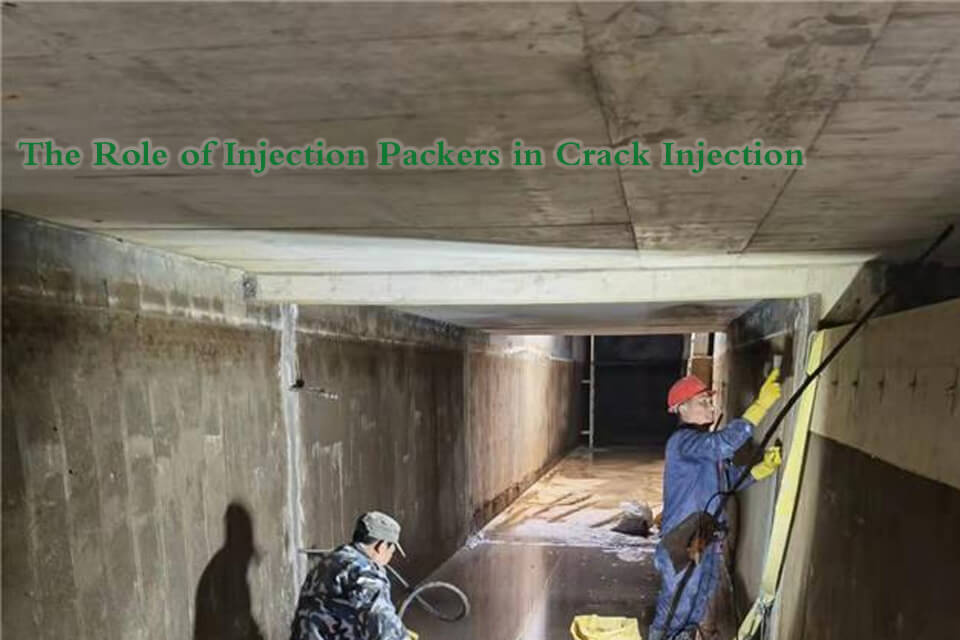

The Role of Injection Packers in Crack Injection and Structural Repair

Crack injection is a critical method used in the restoration and strengthening of concrete structures. It involves injecting an adhesive chemical grout or resin into the cracks of a foundation, slab, or wall to seal and restore structural integrity.

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

What is the Difference Between a Grease Fitting and a Grease Zerk?

If you’re in the world of machinery maintenance, you’ve likely come across the terms “grease fitting” and “grease zerk.”

Understanding Grouting Packers: Essential Tools for Effective Injection Grouting

Injection packers play a vital role in the grouting process, enabling precise injection of grouting materials into cracks, joints, and voids within structures.

What is Crack Injection and Why is Pressure So Important?

Crack injection is a method of repairing concrete structures by forcing a repair material, such as epoxy or polyurethane, into cracks under pressure.