How to Measure a Button Head Grease Fitting: A Complete Guide

Table of Contents

How to Measure a Button Head Grease Fitting

However, choosing the correct size and thread type is essential for a secure and leak-free connection. This guide will walk you through the basics of button head grease fittings, covering how to measure their size accurately, identify metric and SAE threads, and select the right fitting type for your needs.

What is a Button Head Grease Fitting?

A button head grease fitting is a specific type of grease fitting that has a wider, flatter head compared to standard zerk fittings. These fittings are often found on heavy-duty machinery and equipment, as they allow for high-volume grease application. Button head grease fittings are available in a variety of sizes and thread types to fit different types of equipment. They are particularly useful in situations where large amounts of grease need to be delivered quickly.

This type of fitting is commonly seen in construction, mining, and industrial equipment, where regular lubrication is crucial to equipment performance and longevity.

Why is Proper Measurement Important for Grease Fittings?

Measuring your grease fittings correctly is crucial for several reasons:

- Ensures Compatibility: Using the correct fitting size and thread type prevents leaks and ensures a strong, reliable connection.

- Reduces Maintenance Costs: Properly sized fittings reduce wear and tear on equipment by delivering the right amount of grease.

- Improves Efficiency: Accurate measurement helps ensure that grease flows smoothly, reducing the risk of blockage or back-pressure.

Understanding the correct size grease fitting for each piece of equipment can also prevent future complications and maintenance headaches.

Types of Button Head Grease Fittings

Button head grease fittings come in various types, each suited to different applications:

- Flat Button Head: These fittings have a completely flat head and are suitable for applications where space is limited.

- Large Button Head: Ideal for high-volume grease applications, these have a slightly larger head for greater grease flow.

- Metric and SAE Options: Button head grease fittings come in both metric and SAE (Society of Automotive Engineers) sizes, ensuring compatibility with equipment from different regions.

Choosing the correct type of button head fitting depends on the machinery’s requirements and the application’s needs.

How to Measure Grease Fitting Size

To measure a button head grease fitting, follow these steps:

- Measure the Head Diameter: Use a caliper to measure the diameter of the button head. Accurate measurements are essential, as even a slight discrepancy can lead to compatibility issues.

- Determine the Thread Size: Examine the fitting’s threads to determine the diameter and length. For accurate measurement, use a thread gauge or thread pitch tool.

- Check the Thread Pitch: Measure the thread pitch to confirm the fitting’s thread type. Metric fittings, for example, will have different thread pitches compared to SAE fittings.

By following these steps, you can ensure that your button head grease fitting matches your equipment specifications precisely.

Understanding Metric and SAE Grease Fitting Standards

Button head grease fittings come in both metric and SAE standards. Understanding the difference between these standards helps ensure you’re selecting a fitting that’s compatible with your equipment.

- Metric Fittings: Used widely outside of North America, metric fittings are defined by diameter and thread pitch in millimeters. They are commonly used in machinery produced in Europe or Asia.

- SAE Fittings: Often used in North American-made equipment, SAE fittings are measured in inches and follow specific standards for thread pitch and diameter.

Knowing whether your equipment requires metric or SAE fittings is essential for accurate measurement and compatibility.

How to Identify Thread Pitch and Thread Gauge

Accurately identifying thread pitch and thread gauge is vital for matching grease fittings to the correct coupler. Here’s how to do it:

- Use a Thread Gauge: Thread gauges help measure the distance between threads. Place the gauge against the fitting threads and match the gauge to the thread pitch.

- Check the Diameter: Measure the thread diameter with a caliper to confirm the fitting size. For metric threads, this measurement will be in millimeters; for SAE, it will be in inches.

- Identify Thread Type: Determine if the thread is a tapered thread(often seen in high-pressure applications) or a parallel thread (common in general-purpose applications).

With these measurements, you’ll be able to determine the correct grease fitting size and thread type for your needs.

Common Grease Fitting Thread Types

Grease fittings come with different thread types, each suited to specific equipment and applications:

Thread Type | Description | Applications |

SAE | Common in North America; uses inch measurements | General-purpose machinery |

Metric | Widely used in European and Asian machinery | Industrial equipment outside of North America |

NPT | Tapered thread for high-pressure applications | Heavy-duty and high-pressure machinery |

BSP | British Standard Pipe, used in some European machinery | Specialized equipment in Europe and UK |

Understanding these thread types helps ensure that your grease fittings are compatible with your grease gun coupler and other equipment.

Tools Needed for Accurate Measurement

Accurate measurement of grease fittings requires a few essential tools:

- Calipers: For measuring the diameter of the fitting head and threads.

- Thread Gauge: Helps determine thread pitch accurately.

- Ruler or Measuring Tape: For quick reference measurements.

- Lubricant Manual: Many manuals provide specifications for compatible grease fittings.

These tools allow for precise measurement, ensuring compatibility with your grease fittings and couplers.

How to Choose the Right Grease Fitting for Your Equipment

Selecting the correct grease fitting size and type is important for optimal equipment performance. Here’s how to make the best choice:

- Match Fitting Type with Equipment: Determine if your machinery requires button head fittings or standard zerk fittings.

- Consider Thread Compatibility: Verify whether the fitting requires metric or SAE threads based on equipment origin and design.

- Evaluate Grease Volume Needs: For machinery requiring high grease volumes, button head fittings with larger heads might be the best option.

Choosing the right fitting prevents leaks and improves maintenance efficiency, prolonging equipment life.

Troubleshooting Common Measurement Issues

While measuring grease fittings, you may encounter some challenges:

- Inaccurate Measurements: Use a quality caliper or thread gauge to avoid errors in measurement.

- Misidentifying Thread Type: Confirm whether threads are metric or SAE, as this can impact compatibility.

- Difficulty with Access: For hard-to-reach fittings, use a flexible coupler or extension to facilitate measurement and greasing.

If these issues arise, taking a methodical approach and using the proper tools will help you resolve them.

FAQs on Button Head Grease Fittings

What if I can’t find the exact fitting size I need?

Many manufacturers offer adapters to fit non-standard sizes.

How can I tell if a fitting is metric or SAE?

Metric fittings often have “M” markings, while SAE fittings use inch-based markings.

Do I need a specific grease coupler for button head fittings?

Yes, certain grease couplers are compatible with button head fittings, and a coupler that’s too loose may cause grease leakage.

Summary of Key Points for Measuring Button Head Grease Fittings

- Understanding Sizes: Button head fittings come in various sizes suited to specific applications.

- Metric vs. SAE: Determine whether your equipment requires metric or SAE fittings to ensure compatibility.

- Thread Identification: Use thread gauges and calipers for accurate thread and diameter measurements.

- Right Tool Selection: Investing in quality measurement tools aids in achieving accurate results and compatibility.

With this guide, you’re now equipped to measure, identify, and select the best button head grease fitting for your equipment, helping maintain peak performance and efficiency.

Comments

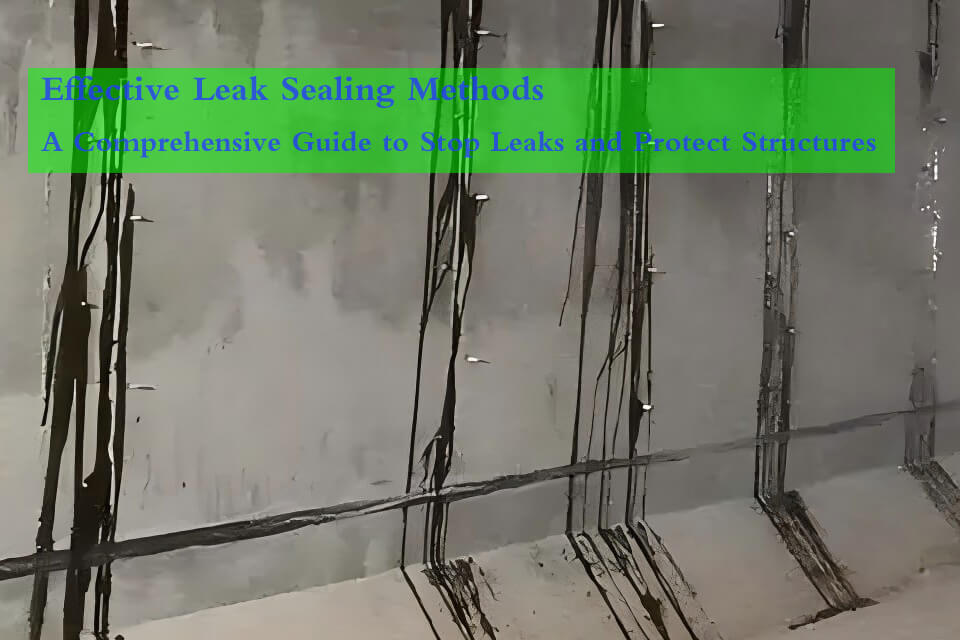

Effective Leak Sealing Methods: A Comprehensive Guide to Stop Leaks and Protect Structures

Leaks can occur in a wide range of environments, from commercial buildings to homes, and even industrial facilities.

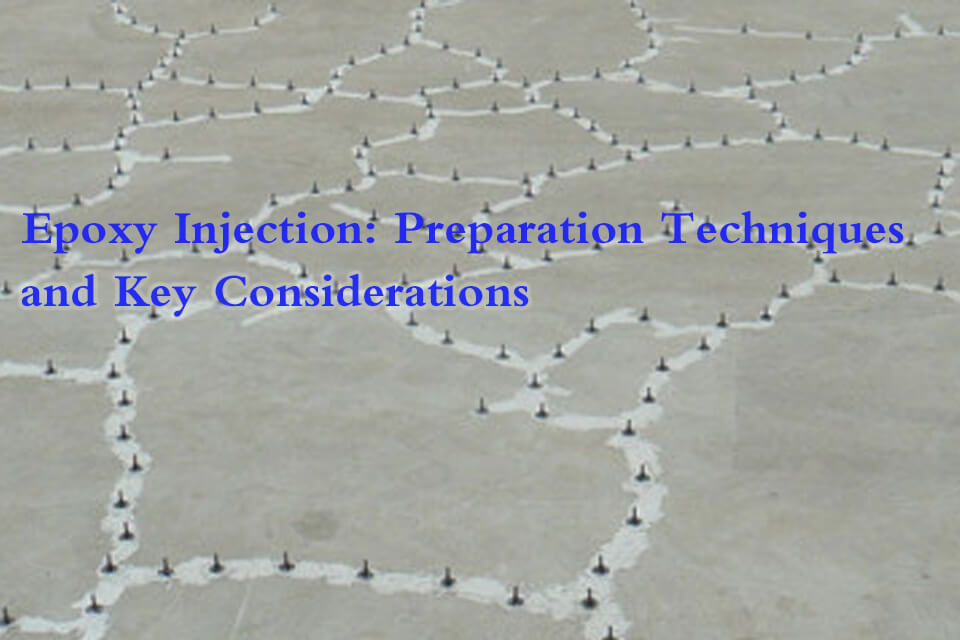

Epoxy Injection: Preparation Techniques and Key Considerations

Epoxy injection is a sophisticated technique employed in the restoration of concrete structures by delivering a high-strength, low-viscosity epoxy resin into cracks.

Chemical Grouting for Soil Stabilization: A Complete Guide to the Process and Benefits

Chemical grouting is an effective method for soil stabilization and strengthening structures in construction and civil engineering.

Are There Different Size Grease Couplers? A Guide to Finding the Right Fit for Your Equipment

Grease couplers are essential tools in maintaining machinery and crack injection, ensuring that lubrication reaches all the critical parts that keep equipment running smoothly.

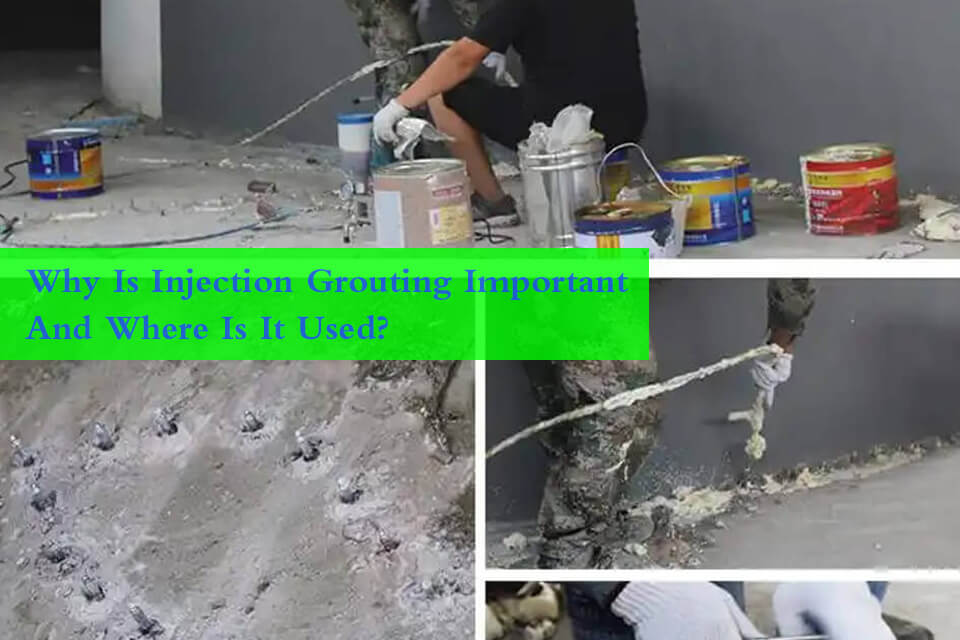

Why Is Injection Grouting Important and Where Is It Used?

Injection grouting is a vital process in construction and repair, designed to enhance the durability and integrity of concrete and masonry structures.

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

Concrete Crack Injection: An Essential Guide to Durable Crack Repair

Concrete structures are built to be strong and long-lasting, but even the best concrete can develop cracks over time.

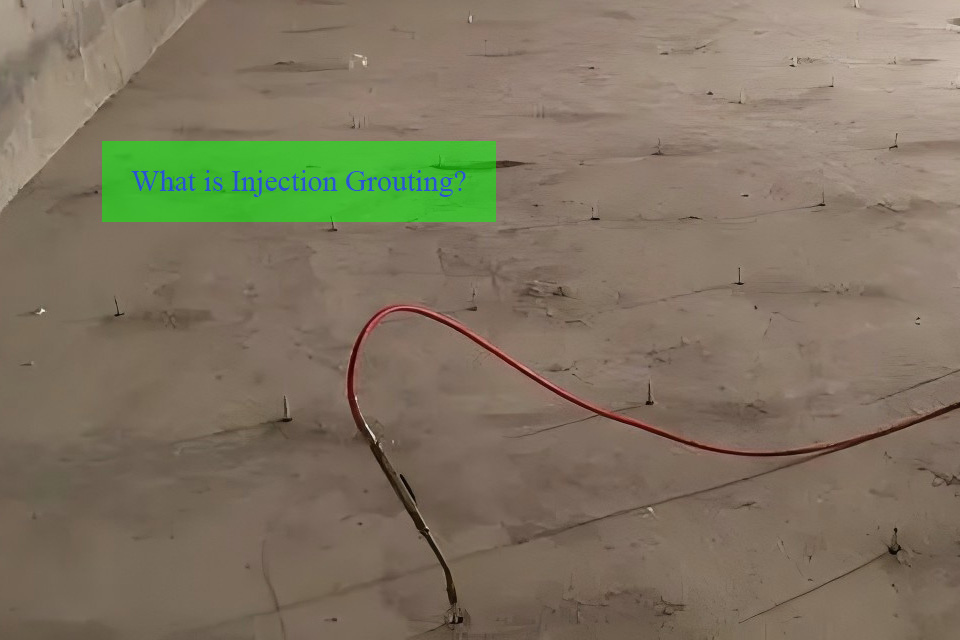

What is Injection Grouting? A Comprehensive Guide to its Benefits, Techniques, and Applications

Injection grouting is an essential process in construction and civil engineering, used to strengthen structures, waterproof surfaces, and fill voids.

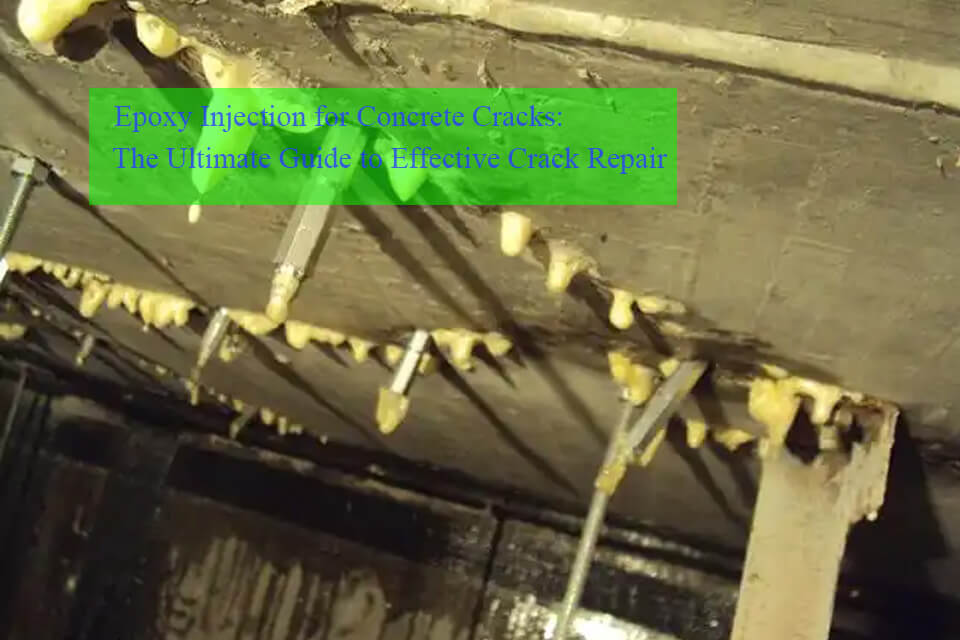

Epoxy Injection for Concrete Cracks: The Ultimate Guide to Effective Crack Repair

Concrete cracks can jeopardize the integrity of any structure, from foundations to walls, but epoxy injection offers a powerful solution for repairing and sealing these cracks.