Discover the Best Grout Pump Machines for Efficient Concrete Applications

Table of Contents

Discover the Best Grout Pump Machines for Efficient Concrete Applications

If you’re curious about how these machines make building easier and safer, you’re in the right place! This article will guide you through everything you need to know about grout pump machines and why they’re so important.

What Is a Grout Pump Machine?

A grout pump machine is a device used to inject grout—a mixture of water, cement, sand, and sometimes other additives—into spaces or voids in construction. This process, known as grouting, helps to fill cracks, reinforce foundations, and bind building elements together.

Why Do We Use Grout Pumps?

Using a grout pump makes the grouting process faster and more efficient. Instead of manually applying grout, which can be messy and time-consuming, a pump delivers the mixture precisely where it’s needed. This ensures a thorough fill and a stronger, more durable construction.

How Do Grout Pump Machines Work?

Grout pumps work by moving the grout mixture from a hopper (where the mix is poured) through a hose and into the desired location. The machine uses pressure to push the grout out, which can be adjusted depending on the job’s needs.

Parts of a Grout Pump Machine

- Hopper: Holds the grout mixture.

- Pump: Moves the grout through the system.

- Hose: Channels the grout to the application site.

- Nozzle: Controls the flow and direction of the grout.

Types of Grout Pump Machines

There are different types of grout pump machines, each suited for specific applications.

Manual Grout Pumps

These are simple pumps that require human effort to operate. They’re perfect for small jobs or areas where power sources aren’t available.

Electric Grout Pumps

Electric grout pumps use electricity to power the pump. They’re efficient and ideal for medium to large projects where consistent power is needed.

Hydraulic Grout Pumps

Hydraulic pumps use fluid power to move the grout. They’re powerful and can handle heavy-duty tasks, making them suitable for large construction sites.

When Do You Need a Heavy-Duty Grout Pump?

For big projects like building bridges or large buildings, a heavy-duty grout pump is necessary. These pumps can handle thicker mixtures and pump grout over longer distances.

Benefits of Heavy-Duty Grout Pumps

- High Pressure: Can push grout into deep or hard-to-reach areas.

- Durable: Built to last and handle tough jobs.

- Efficient: Saves time on large projects.

What Are Common Applications of Grout Pumps?

Grout pumps are used in various construction tasks:

- Foundation Repair: Filling cracks and strengthening bases.

- Concrete Slab Lifting: Raising sunken concrete surfaces.

- Pier and Beam Support: Reinforcing structures.

- Tunnel Construction: Sealing and stabilizing tunnels.

How to Choose the Right Grout Pump for Your Project

Selecting the right grout pump depends on your project’s needs.

Factors to Consider

- Type of Grout: Cement, sand, or slurry mixtures.

- Pressure Requirements: High-pressure pumps for deep injections.

- Power Source: Electric or hydraulic power.

- Portability: Wheel-mounted pumps for easy movement.

- Capacity: Size of the hopper and pump output (measured in GPM—gallons per minute).

What Is a Grout Mixer, and Do You Need One?

A grout mixer is a machine that mixes grout ingredients to a consistent texture. While some grout pumps have built-in mixers, others require a separate mixer.

Advantages of Using a Grout Mixer

- Consistency: Ensures the mixture is even.

- Efficiency: Saves time compared to mixing by hand.

- Quality: Improves the strength of the grout.

Tips for Easy Operation of Grout Pump Machines

Operating a grout pump can be straightforward with a few tips:

- Read the Manual: Always start by understanding your machine.

- Safety First: Wear protective gear.

- Regular Maintenance: Keep the machine clean and check for wear.

- Practice: Start with small projects to gain confidence.

Where Can You Find Grout Pumps for Sale?

Grout pumps can be purchased from construction equipment suppliers or specialized manufacturers. When looking for grout pumps for sale, consider:

- Reputation: Buy from trusted sellers.

- Warranty: Ensure there’s coverage for defects.

- Support: Access to customer service and parts.

The Role of Grout Pumps in Cement Injection

Cement injection involves pumping cement grout into the ground or structures to improve stability.

How Grout Pumps Aid Cement Injection

- Precision: Delivers grout exactly where needed.

- Control: Adjust pressure and flow for different conditions.

- Versatility: Suitable for various soil types and structures.

Understanding the Importance of Grout Pump Accessories

Accessories enhance the functionality of grout pumps.

Common Accessories

- Nozzles: Different sizes for various applications.

- Hoses: Extended lengths for hard-to-reach areas.

- Mixing Paddles: For grout mixers.

- Replacement Parts: To keep your pump running smoothly.

Final Thoughts on Choosing the Best Grout Pump Machine

Selecting the best grout pump machine can make a big difference in your project’s success. By understanding your needs and the features of different pumps, you can make an informed choice.

Quick Tips

- Consider the size and scope of your project.

- Think about the type of grout you’ll be using.

- Don’t forget about maintenance and ease of use.

Summary: Key Points to Remember

- Grout pumps make construction tasks easier by efficiently delivering grout.

- There are manual, electric, and hydraulic grout pumps for different needs.

- Heavy-duty pumps are best for large, demanding projects.

- Always choose the right pump based on your project’s requirements.

- Accessories and maintenance are important for the long-term use of your grout pump.

By keeping these points in mind, you’re well on your way to selecting the perfect grout pump machine for your construction needs!

Comments

How Do I Know What Size Grease Fitting I Need?

Grease fittings are small but crucial components in machinery maintenance, helping keep equipment running smoothly by allowing grease to reach vital parts.

Key Benefits of Using Injection Packers for Concrete Repair

Injection packers are an essential tool for addressing cracks and structural deficiencies in concrete. These devices allow for precise application of repair materials

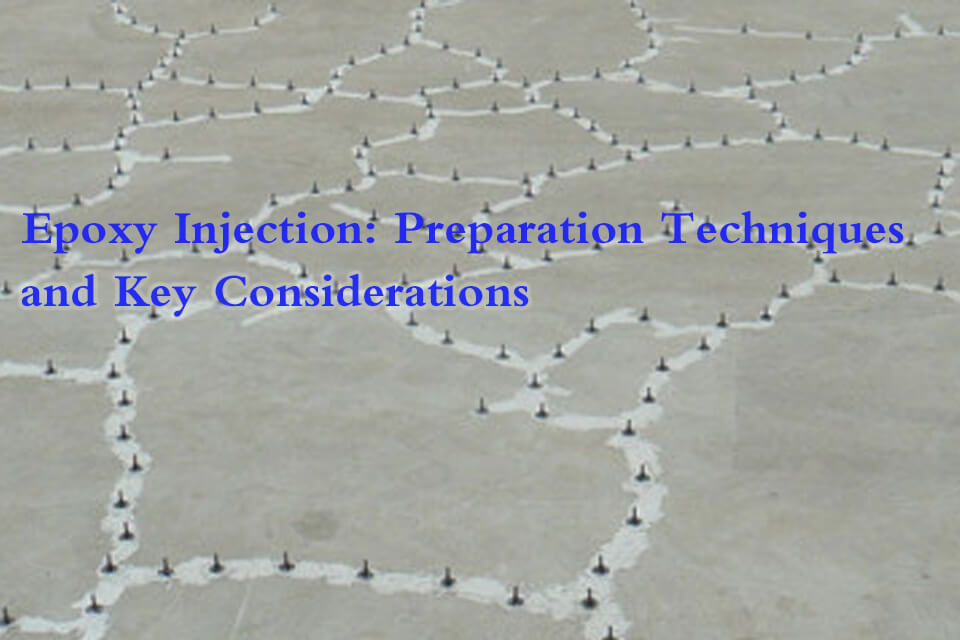

Epoxy Injection: Preparation Techniques and Key Considerations

Epoxy injection is a sophisticated technique employed in the restoration of concrete structures by delivering a high-strength, low-viscosity epoxy resin into cracks.

Effective Use of Injection Packers for Bridge Crack Repairs

Cracks in bridges can lead to leaks, structural weaknesses, and increased repair costs if not promptly addressed

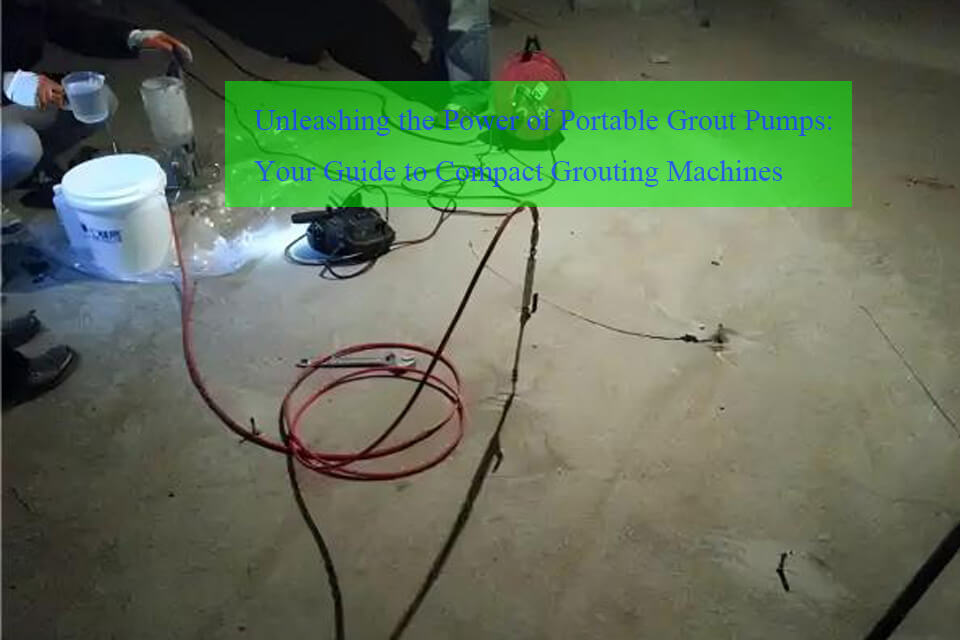

Unleashing the Power of Portable Grout Pumps: Your Guide to Compact Grouting Machines

Looking to tackle a construction project that involves grouting but worried about heavy equipment? Discover how portable grout pumps can revolutionize your work!

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

Effective Crack Injection for Concrete Repair: Step-by-Step Guide

Concrete cracks are a common issue in many structures, often leading to leaks that can cause significant damage if not properly sealed. Crack injection is a highly effective technique for repairing these cracks and stopping water infiltration.

What is the Injection Grouting Procedure? A Detailed Guide to Concrete and Masonry Repairs

Injection grouting is a crucial technique used in construction and maintenance for repairing and reinforcing concrete and masonry structures.

Concrete Repair: The Innovative Concrete Crack Repair Injector

The Concrete Crack Repair Injector is a self-contained, high-efficiency device designed specifically for the repair of cracks in concrete structures.