Unleashing the Power of Portable Grout Pumps: Your Guide to Compact Grouting Machines

Looking to tackle a construction project that involves grouting but worried about heavy equipment? Discover how portable grout pumps can revolutionize your work!

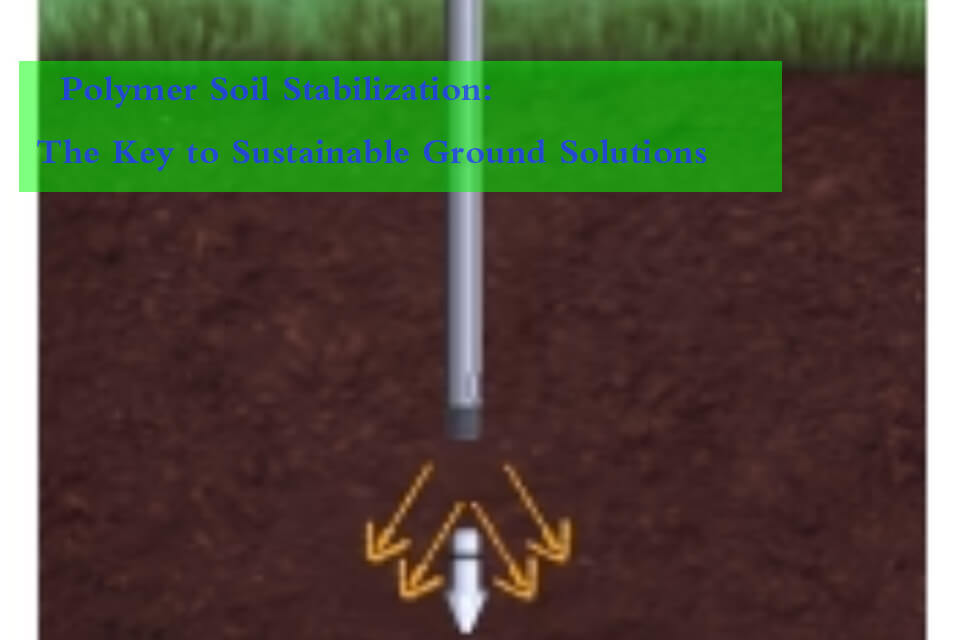

Polymer Soil Stabilization: The Key to Sustainable Ground Solutions

Soil stabilization is vital in construction and civil engineering, particularly for enhancing soil properties and ensuring durable infrastructure.

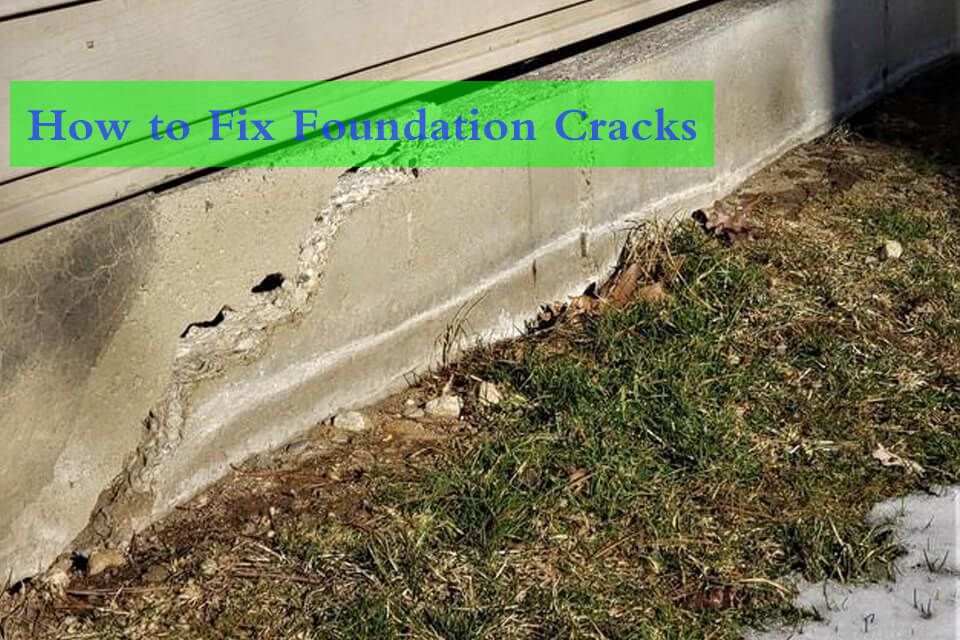

How to Fix Foundation Cracks: A Comprehensive Guide

Foundation cracks can jeopardize the structural integrity of any building, posing a risk to both property and safety.