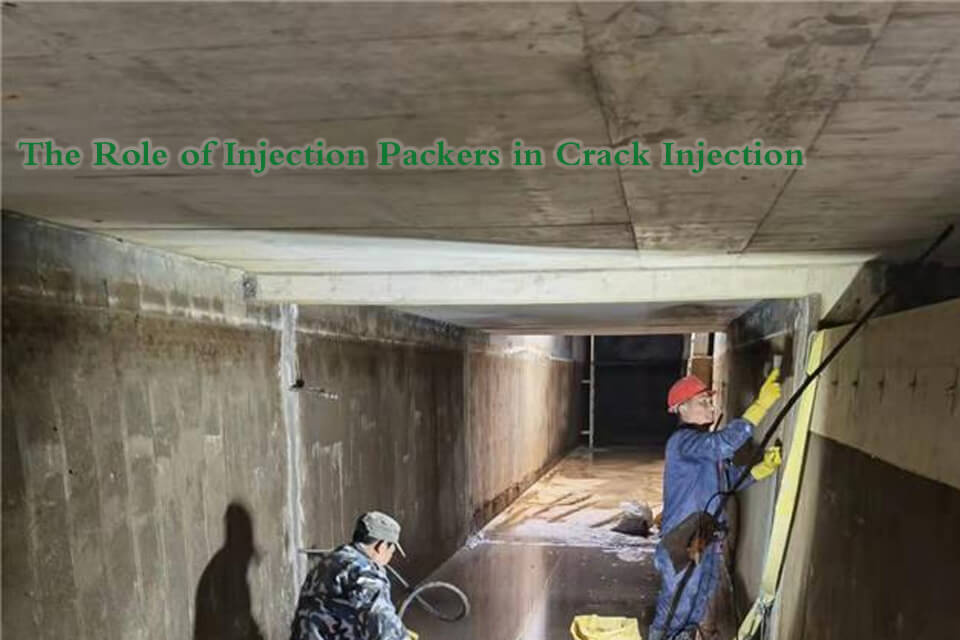

The Role of Injection Packers in Crack Injection and Structural Repair

Crack injection is a critical method used in the restoration and strengthening of concrete structures. It involves injecting an adhesive chemical grout or resin into the cracks of a foundation, slab, or wall to seal and restore structural integrity.

Concrete Repair: The Innovative Concrete Crack Repair Injector

The Concrete Crack Repair Injector is a self-contained, high-efficiency device designed specifically for the repair of cracks in concrete structures.

How to Epoxy Injection Concrete Cracks: A Comprehensive Guide

Concrete structures are prone to cracking over time due to various factors such as natural settling, temperature changes, and heavy loads.