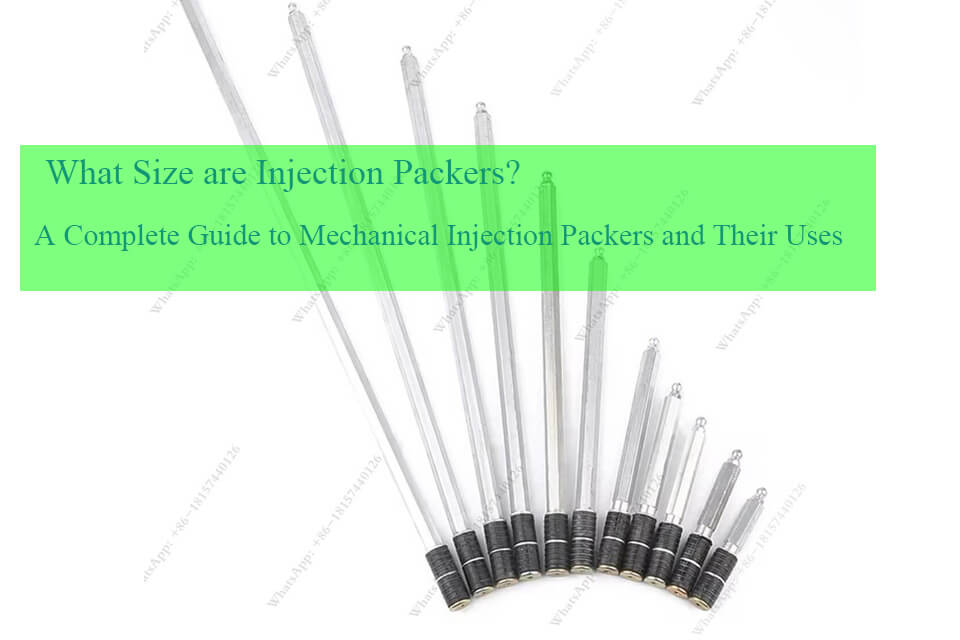

What Size are Injection Packers? A Complete Guide to Mechanical Injection Packers and Their Uses

Table of Contents

Summary

Choosing the correct packer size affects the efficiency, pressure, and distribution of repair materials like epoxy and polyurethane. This article will guide you through selecting the right injection packer for various applications, enhancing the effectiveness of your injection processes.

What is an Injection Packer?

An injection packer, often called a mechanical packer, is a small tool inserted into a drilled hole within concrete to facilitate the controlled injection of repair materials. Injection packers are essential in structural repair because they provide a secure, leak-proof channel through which epoxy or polyurethane can be injected under pressure, ensuring deep penetration into cracks

Why is the Size of Injection Packers Important?

Packer size influences how deeply materials penetrate and how well they fill the voids within cracks. Choosing the correct diameter ensures the packer fits the drilled hole snugly, avoiding leaks and pressure drops. An undersized packer may cause insufficient injection, while an oversized packer could damage the crack edges, leading to further structural issues.

Types of Mechanical Injection Packers

Packers are available in a range of materials, each suited for specific pressure levels and environments:

- Plastic Packers: Ideal for low-pressure applications, such as small cracks in non-structural areas.

- Steel Packers: Known for durability, these are best for high-pressure injections.

- Aluminum and Zinc Packers: Lightweight but durable, these packers provide a balance between performance and affordability.

How Do Mechanical Injection Packers with Zerk Fittings Work?

Zerk fittings are small components on packers that allow for easy lubrication, which is critical in high-pressure environments. Packers with these fittings are reusable, making them a cost-effective option for large projects requiring repeated injections.

Common Sizes and Diameters of Injection Packers

The following table outlines the common sizes of injection packers and their recommended uses:

| Diameter (mm) | Material | Use Case |

| 10 | Plastic | Fine cracks, low pressure |

| 13 | Steel | Standard cracks |

| 16 | Aluminum | Heavy-duty applications |

The Role of Packers in Epoxy and Polyurethane Injection

Epoxy and polyurethane injection rely on packers to evenly distribute the material. Packers ensure that these substances penetrate deeply, fully sealing cracks for lasting structural integrity.

Steel vs. Plastic vs. Aluminum Packers: Which to Use?

Each material has its advantages:

- Steel packersare the top choice for high-pressure injections.

- Plastic packersare a budget-friendly option for less intense repairs.

- Aluminum packersstrike a balance between durability and cost.

Comparing Mechanical and Plastic Packers

While mechanical packers are often reusable and suited for high-pressure settings, plastic packers tend to be single-use but are ideal for smaller, simpler projects.

Injection Ports and Nipples: What You Need to Know

Injection packers often come with ports and nipples designed to control material flow. Some include Zerk-type nipples, which enhance maintenance and provide better control during injection.

Selecting the Right Injection Packers for Your Project

Consider the following when selecting a packer:

- Crack Width: Smaller cracks require finer packers.

- Material: Choose plastic, steel, or aluminum based on your project’s pressure needs.

- Injection Pressure: High-pressure jobs benefit from steel or aluminum packers.

Conclusion

- Select the Right Size: Properly sized packers are essential for effective crack sealing.

- Material Matters: Steel and aluminum offer durability, while plastic is suitable for smaller tasks.

- Use Zerk Fittings: Zerk fittings enhance reusability, particularly in high-pressure settings.

- Understand Injection Needs: The packer type significantly impacts the effectiveness of epoxy or polyurethane distribution.

This guide has provided insights into choosing the correct injection packer for any job. Proper selection leads to better outcomes, reduced costs, and increased efficiency in concrete repair and waterproofing tasks.

Comments

What Size are Injection Packers? A Complete Guide to Mechanical Injection Packers and Their Uses

When it comes to crack injection and waterproofing, the size and type of mechanical injection packers you use can make all the difference.

Are There Different Size Grease Couplers? A Guide to Finding the Right Fit for Your Equipment

Grease couplers are essential tools in maintaining machinery and crack injection, ensuring that lubrication reaches all the critical parts that keep equipment running smoothly.

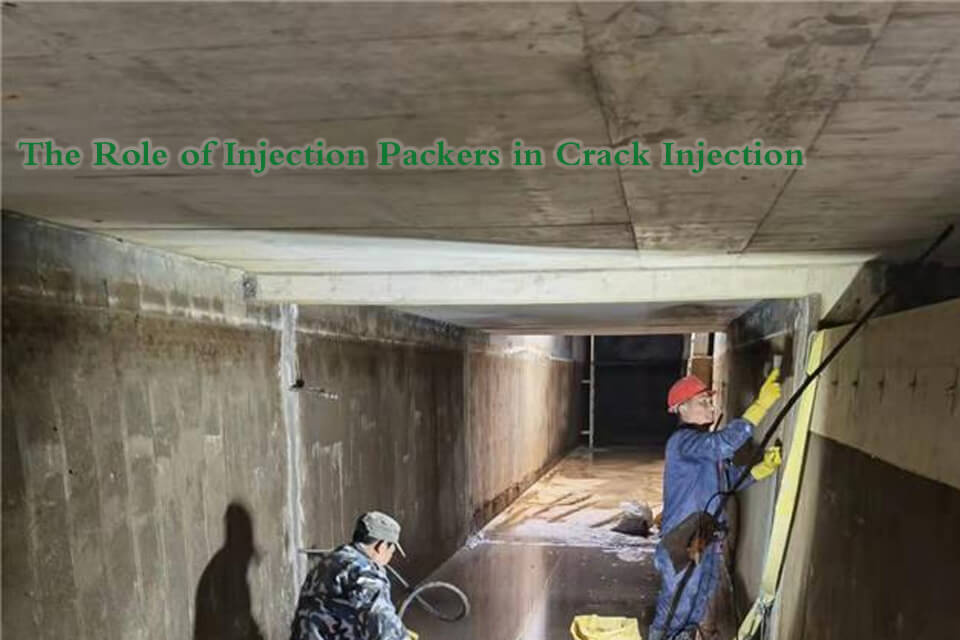

The Role of Injection Packers in Crack Injection and Structural Repair

Crack injection is a critical method used in the restoration and strengthening of concrete structures. It involves injecting an adhesive chemical grout or resin into the cracks of a foundation, slab, or wall to seal and restore structural integrity.

What is the Difference Between a Grease Fitting and a Grease Zerk?

If you’re in the world of machinery maintenance, you’ve likely come across the terms “grease fitting” and “grease zerk.”

The Advantages of Chemical Grouting: Strengthening Structures for a Safer Future

Chemical grouting is a powerful and versatile solution for strengthening soil, sealing leaks, and stabilizing foundations in challenging construction environments.

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

Unlocking the Secrets of Soil Stabilization: A Comprehensive Guide

Soil stabilization is a crucial process in construction and civil engineering that can make or break a project’s success.

Unveiling the Power of Heavy-Duty Electric Grout Pumps: Your Ultimate Guide

Have you ever wondered how large structures stay solid and intact? Grouting plays a key role!

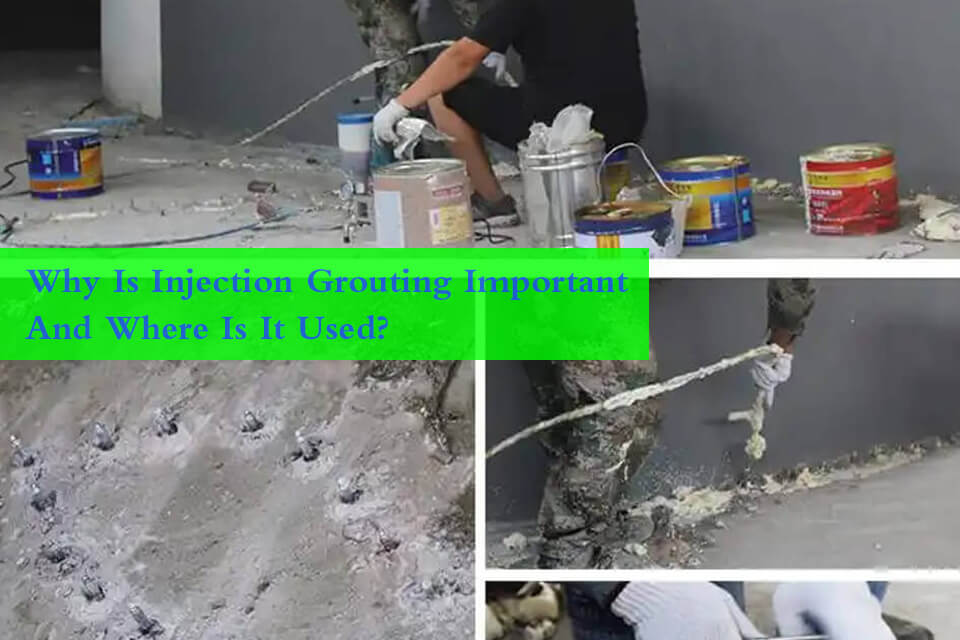

Why Is Injection Grouting Important and Where Is It Used?

Injection grouting is a vital process in construction and repair, designed to enhance the durability and integrity of concrete and masonry structures.