What is the Injection Grouting Procedure? A Detailed Guide to Concrete and Masonry Repairs

Table of Contents

Summary

This method is primarily employed to fill cracks, voids, and gaps within materials, preventing further damage, enhancing structural integrity, and improving waterproofing. Understanding the injection grouting procedure can help you make informed decisions when addressing issues like leaks, cracks, or weakened foundations.

In this article, we will explore the step-by-step procedure of injection grouting, its importance, and how different types of grouting are used in various applications, from concrete repairs to masonry waterproofing.

What is Injection Grouting?

Injection grouting is the process of injecting a specially formulated grout into cracks or voids within a material (like concrete or masonry) to fill those gaps, stabilize the structure, and prevent further deterioration. The grout used can vary depending on the purpose—whether it’s for waterproofing, structural repair, or void filling.

Why is Injection Grouting Important?

- Prevents further damage: Grout injection fills cracks or gaps, preventing water infiltration, which can lead to further deterioration and weakening of the structure.

- Strengthens the structure: Once the grout hardens, it enhances the load-bearing capacity of the material.

- Improves waterproofing: By sealing the cracks, injection grouting creates a water-resistant barrier.

Injection grouting is particularly effective in environments that are subject to moisture, like basements and underground foundations, where it is crucial to stop water infiltration and ensure the stability of the structure.

What is the Step-by-Step Injection Grouting Procedure?

The injection grouting procedure involves a series of well-defined steps to ensure the grout is properly injected and fills the cracks or voids effectively. Here’s a breakdown of the typical procedure:

Step 1: Surface Preparation

Before starting the grouting process, the surface is cleaned to remove any dirt, dust, or debris that could prevent the grout from adhering properly. This step is essential to ensure a strong bond between the grout and the surrounding material.

Step 2: Drilling Injection Holes

Small holes are drilled into the surface of the concrete or masonry structure along the cracks or voids. The spacing and depth of these holes depend on the size of the cracks and the type of grout used. The holes serve as the entry points for the grout.

Step 3: Injection of Grout

Using an injection pump, grout is injected into the cracks under pressure. The grout flows through the drilled holes, filling the voids and cracks as it spreads. The pressure used during this process helps ensure that even the smallest fissures are filled with grout.

Step 4: Curing and Hardening

Once the grout has been injected into the cracks, it needs time to cure and harden. Depending on the type of grout used, curing time may vary. Cement-based grouts typically take longer to set compared to chemical grouts or epoxies.

Step 5: Final Inspection

After the grout has cured, a final inspection is performed to ensure that the cracks are completely sealed and the repair is effective. If necessary, additional grout may be injected, and the surface is smoothed to restore its original appearance.

Why is Injection Grouting Important for Repairs?

Injection grouting plays a vital role in masonry repairs and concrete repairs, especially when dealing with structural damage caused by water infiltration or shifting foundations.

Key Benefits of Injection Grouting

- Restores structural integrity: Injection grouting helps restore and reinforce the strength of the structure by filling cracks and voids, preventing them from spreading.

- Prevents future damage: By sealing the cracks and gaps, grout prevents moisture from entering, which can cause further deterioration or mold growth.

- Cost-effective: Injection grouting is a more affordable and less disruptive option than complete reconstruction or replacement of damaged materials.

Grout injection is particularly important for areas that are exposed to harsh conditions, such as foundations or exterior walls, as it provides a durable solution that can withstand water, weather, and pressure over time.

What Types of Injection Grouting Are Used?

Different types of injection grouting are used depending on the material being repaired, the size and nature of the cracks, and the intended purpose of the repair. Common types of grouting include:

Compaction Grouting

This type of grouting involves injecting a thick grout mixture under pressure to stabilize soil or fill large voids beneath concrete or masonry. It is used in situations where the ground beneath a structure has become loose or unstable.

Chemical Grouting

Chemical grouting involves injecting a chemical-based grout into cracks to create a chemical bond. It is often used for waterproofing or for sealing cracks in environments where water or chemicals are a concern.

Permeation Grouting

Used primarily to create a permeable barrier in the ground, permeation grouting involves injecting grout into soil or concrete to reduce water flow. This is often used in foundation repairs where soil stabilization is required.

Each type of injection grouting is suited for different repair scenarios, making it important to choose the right one based on the material, damage, and environment.

What Are the Key Components of the Injection Grouting Process?

The success of the injection grouting procedure depends on several key components, including the grout material, the injection method, and the equipment used. Here’s a closer look at each element:

Types of Grout Used

- Cementitious Grouts: Commonly used for general repair work in concrete and masonry, these grouts are made from a mixture of cement, sand, and water.

- Epoxy Grouts: These grouts are often used in high-pressure injectionsituations where a strong bond is required, such as in concrete that is exposed to heavy stress or moisture.

- Polyurethane Grouts: These are used primarily for waterproofing They expand when injected, filling cracks and preventing further water leakage.

Injection Techniques

- Low-pressure injection: This method is ideal for filling smaller cracks or voids and is used when the grout doesn’t need to penetrate deeply into the material.

- High-pressure injection: Used for larger cracks or voids, high-pressure injection ensures deeper penetration of grout into the material, which is especially effective for waterproofing.

What is High-Pressure Injection Grouting?

High-pressure injection grouting is a method of injecting grout into cracks or voids at a much higher pressure compared to standard injection methods. This technique is used when deeper penetration of the grout is needed, such as in large cracks or when there is significant water infiltration

When to Use High-Pressure Injection

- Concrete repair: High-pressure injection can fill large, deep cracks in concrete, restoring its integrity.

- Masonry repair: It is also useful in repairing masonry walls with significant cracks or voids.

- Waterproofing: High-pressure injection is crucial when sealing cracks in underground structures, such as basements, to prevent water infiltration.

How Does Injection Grouting Help in Concrete Repair?

Injection grouting is one of the most effective methods for repairing concrete, particularly for sealing cracks and voids. By injecting grout into damaged concrete, the material is filled and solidified, which restores its strength and prevents further damage.

Applications in Concrete Repairs

- Crack Sealing: Grout is injected into cracks to prevent further water infiltration, which can cause corrosion and weaken the concrete.

- Void Filling: When there are voids or cavities beneath concrete slabs, grout fills these spaces to stabilize the surface and prevent settlement or collapse.

How Long Does Injection Grouting Last?

One of the biggest advantages of injection grouting is its long-lasting results. When performed correctly, the grouting procedure can provide a permanent solution to cracks and voids in concrete and masonry.

Longevity of Grouting

- Durable repairs: Once the grout hardens and bonds with the surrounding material, it forms a solid and durable barrier.

- Minimal maintenance: Once injected and cured, the grout typically requires little to no maintenance, although periodic inspections can help identify any potential issues early.

What Equipment Is Required for the Injection Grouting Procedure?

The following equipment is typically used during the injection grouting process:

- Injection pumps: Used to apply pressure to the grout during injection.

- Injection ports: These are installed along the cracks to direct the grout into the right spots.

- Grout mixing equipment: Used to prepare the grout mixture for injection.

Choosing the correct tools and equipment is crucial for ensuring the effectiveness of the injection grouting procedure.

Conclusion

- Injection groutingis a vital technique for repairing cracks, voids, and gaps in concrete and masonry.

- The procedure involves surface preparation, drilling injection holes, grout injection, curing, and a final inspection.

- Different types of injection groutingare available, including chemical grouting, compaction grouting, and permeation grouting.

- High-pressure injectionis used for deeper cracks and for applications requiring stronger bonds, such as waterproofing.

- Proper equipment, including injection pumpsand grout mixers, is essential for a successful repair.

By understanding the injection grouting procedure, you can make informed decisions about repairs and ensure long-lasting, reliable results for your concrete and masonry structures.

Comments

The Power of PU Injection: Effective Waterproofing for Cracks and Leaks

Polyurethane (PU) injection is a powerful method for waterproofing cracks and leaks in concrete structures.

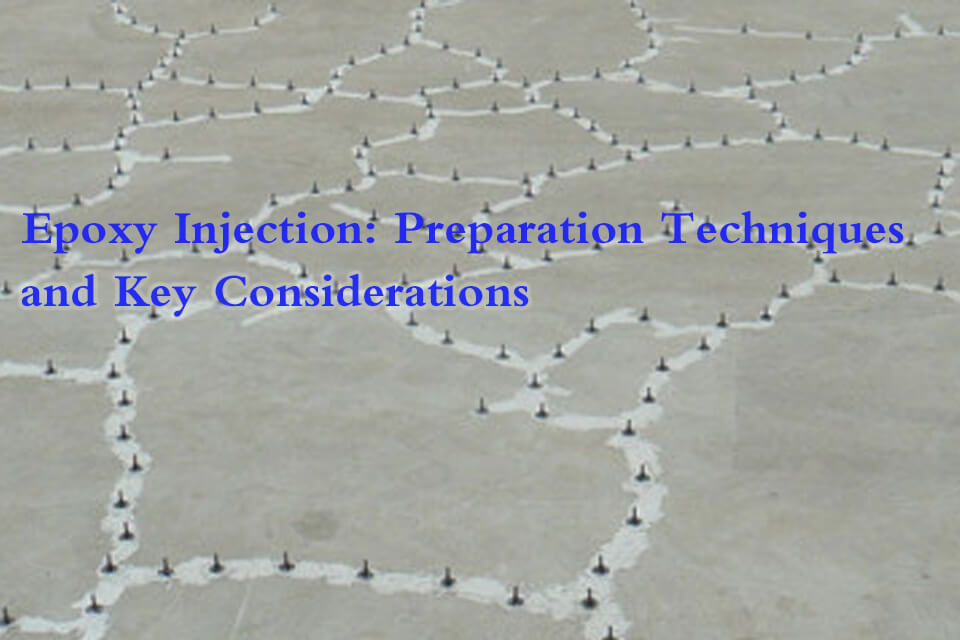

Epoxy Injection: Preparation Techniques and Key Considerations

Epoxy injection is a sophisticated technique employed in the restoration of concrete structures by delivering a high-strength, low-viscosity epoxy resin into cracks.

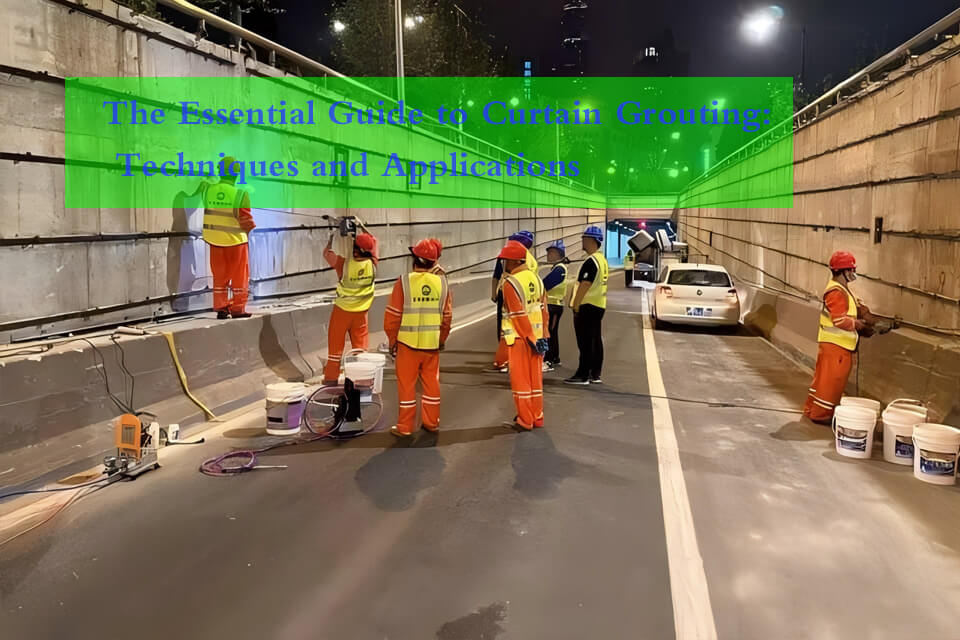

The Essential Guide to Curtain Grouting: Techniques and Applications

Curtain grouting is a revolutionary technique in the construction industry, particularly vital for preventing leaks and reinforcing structures.

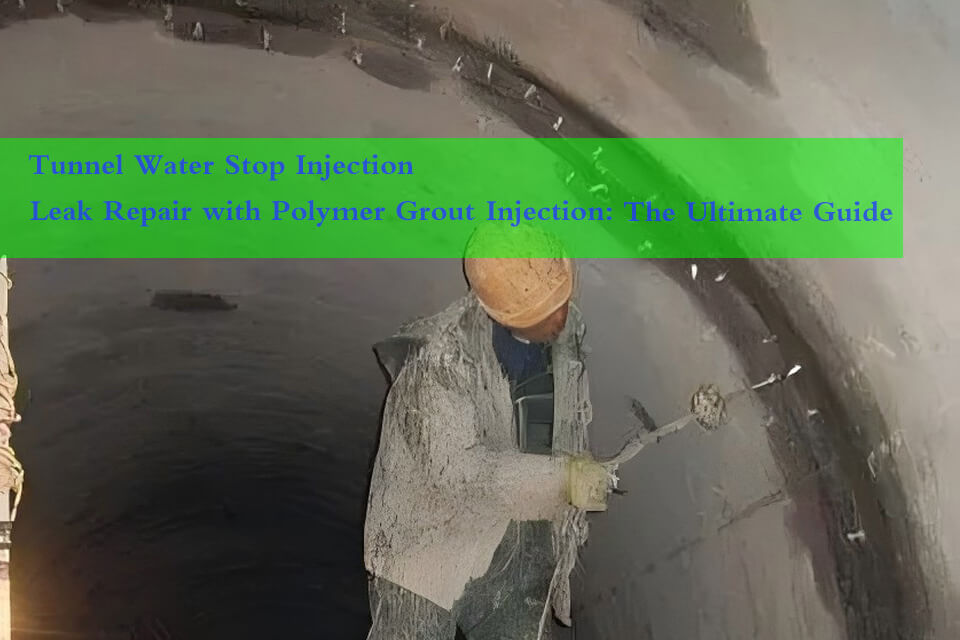

Expert Guide: Tunnel Water Stop Injection – Advanced Solutions for Leak Repair

Are you dealing with water intrusion in your tunnel infrastructure? Water leakage in tunnels can lead to serious structural issues and operational disruptions.

How to Epoxy Injection Concrete Cracks: A Comprehensive Guide

Concrete structures are prone to cracking over time due to various factors such as natural settling, temperature changes, and heavy loads.

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

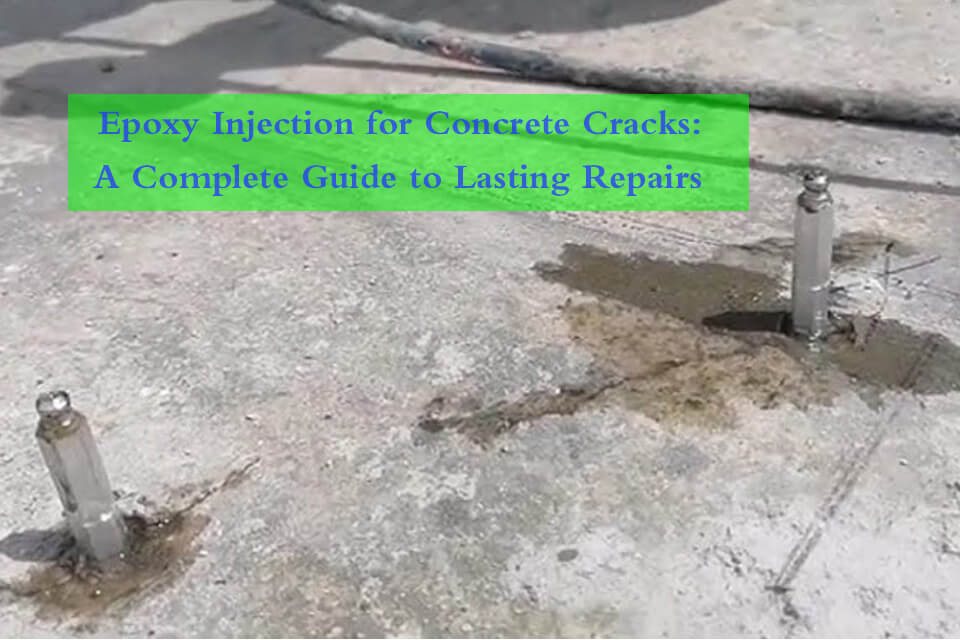

Epoxy Injection for Concrete Cracks: A Complete Guide to Lasting Repairs

In this article, learn how epoxy injection effectively restores structural integrity to cracked concrete, providing a durable, lasting solution.

Injection Lances for Soil Stabilization: A Technical Overview

Injection lances are essential tools for soil stabilization and ground reinforcement, designed to improve the structural integrity of the soil by injecting stabilizing agents at precise depths.

The Power of PU Injection: Effective Waterproofing for Cracks and Leaks

Polyurethane (PU) injection is a powerful method for waterproofing cracks and leaks in concrete structures.