What is the Difference Between a Grease Fitting and a Grease Zerk?

If you’re in the world of machinery maintenance, you’ve likely come across the terms “grease fitting” and “grease zerk.”

How Do I Know What Size Grease Fitting I Need?

Grease fittings are small but crucial components in machinery maintenance, helping keep equipment running smoothly by allowing grease to reach vital parts.

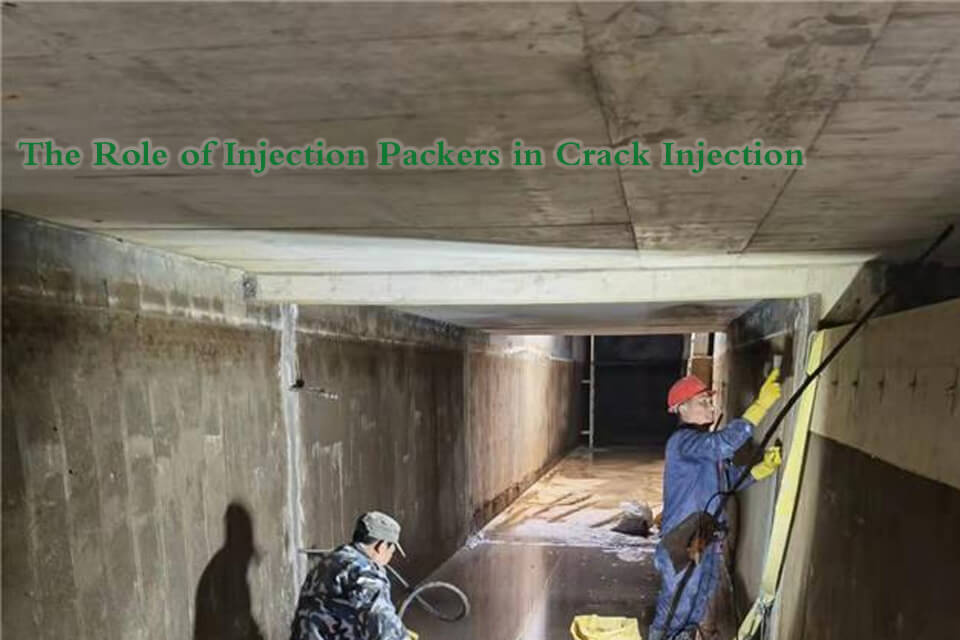

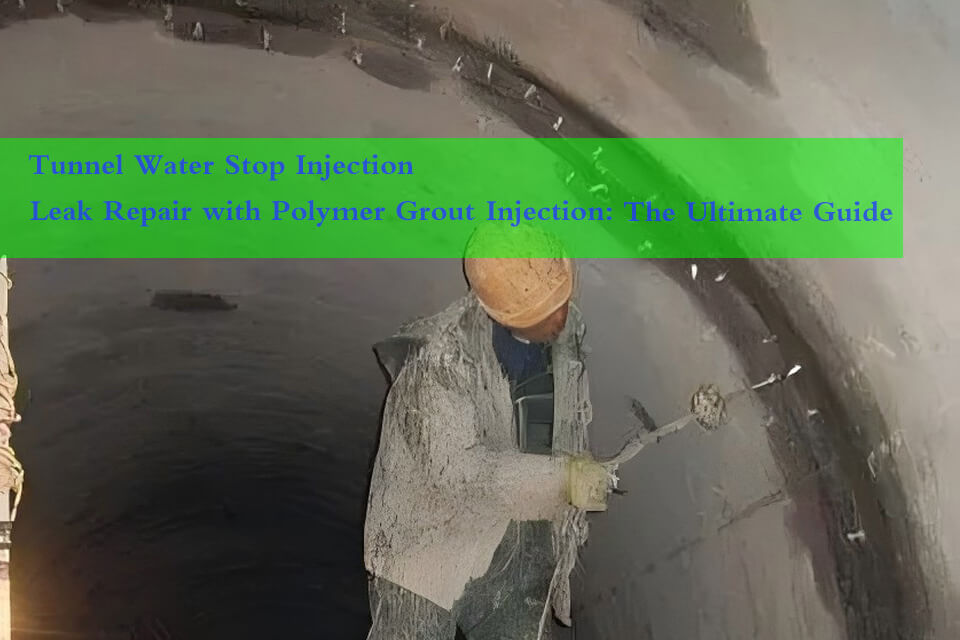

Key Benefits of Using Injection Packers for Concrete Repair

Injection packers are an essential tool for addressing cracks and structural deficiencies in concrete. These devices allow for precise application of repair materials