Unveiling the Power of Heavy-Duty Electric Grout Pumps: Your Ultimate Guide

Table of Contents

Unveiling the Power of Heavy-Duty Electric Grout Pumps

In this guide, we’ll explore the world of heavy-duty electric grout pumps, especially the heavy-duty ones. We’ll dive into how they work, why they’re essential, and how they make construction projects safer and more efficient. If you’re curious about construction tools or planning a project, this article is for you!

What Is Grouting and Why Is It Important?

Grouting is like giving a building a strong handshake. It fills the gaps and spaces in structures with a fluid material called grout. This process strengthens the structure and keeps it stable.

- Grout: A mixture usually made of water, cement, and sand.

- Purpose: To fill voids and reinforce structures.

Grouting ensures that buildings, bridges, and even underwater structures stay put and do their job well

How Do Electric Grout Pumps Work?

Electric grout pumps are machines that help push grout into spaces where it’s needed.

- Electric Power: They use electricity to operate, making them efficient and easy to control.

- Pump Mechanism: They have a single-cylinderor auto reciprocating pump system that moves the grout smoothly.

These pumps make grouting faster and more precise. Imagine trying to squeeze toothpaste back into the tube without a tool—tough, right? Electric grout pumps make the job easy!

Why Choose Heavy-Duty Grout Pumps?

Not all pumps are created equal. Heavy-duty grout pumps are like the superheroes of construction sites.

- Durability: Built to handle tough jobs without breaking down.

- Capacity: Can pump large amounts of grout quickly.

- Versatility: Suitable for various grout applications.

They are essential for big projects where regular pumps just won’t cut it.

What Are the Key Features of a Good Grout Pump?

When picking a grout pump, look for these features:

- Protected Pressure Gauge: Shows you how much pressure is in the pump to prevent overloading.

- Grout Hose and Nozzle: Grout hosesconnect the pump to the application area, and nozzles control the flow.

- Hopper: Where you pour in the grout mix. A good hopperis easy to fill and clean.

- Mixer Compatibility: Some pumps come with or connect to a mixerto keep the grout consistent.

These features ensure the pump works efficiently and lasts longer.

How Does the Auto Reciprocating Pump Benefit You?

An auto reciprocating pump moves back and forth automatically.

- Efficiency: Pumps grout continuously without manual intervention.

- Consistency: Provides a steady flow of grout for uniform application.

This means less work for you and a better end result.

Can Electric Grout Pumps Handle All Grouting Needs?

While electric grout pumps are versatile, it’s essential to match the pump to your project.

- Capacity: Check if the pump can handle the volume you need.

- Material Compatibility: Ensure it’s suitable for your grout type.

For specialized jobs, consult with experts like Kenrich Products to find the perfect match.

How to Maintain Your Grout Pump for Longevity?

Taking care of your pump ensures it stays in top shape.

- Regular Cleaning: Clean the hopper, grout hose, and nozzleafter each use.

- Check the Pressure Gauge: Ensure the protected pressure gaugeis functioning.

- Inspect Hoses: Look for wear and tear to prevent leaks.

Regular maintenance saves money and prolongs the life of your equipment.

What Safety Measures Should You Follow?

Safety first!

- Wear Protective Gear: Gloves and goggles protect you from splashes.

- Follow Instructions: Read the manual thoroughly.

- Monitor Pressure: Keep an eye on the pressure gauge to avoid accidents.

Being careful keeps you and your team safe on the job

Where Can You Find Reliable Grout Pumps?

Choosing a reputable supplier is key.

- Kenrich Products: Known for quality and reliability.

- May Also Like: Explore other trusted brands and compare features.

Investing in a good pump pays off in performance and durability.

How Are Grout Pumps Impacting Modern Construction?

Grout pumps have revolutionized construction.

- Efficiency: Projects are completed faster.

- Precision: Accurate application reduces waste.

- Innovation: New features like water batchersimprove the process.

They are essential tools that keep the industry moving forward.

Conclusion: Boost Your Project with the Right Grout Pump

Understanding electric grout pumps empowers you to make the best choice for your project. Whether you’re a professional or a DIY enthusiast, the right pump makes all the difference.

Key Takeaways:

- Grouting strengthens structures, and pumps make the process efficient.

- Electric and heavy-duty grout pumpsare powerful tools for big projects.

- Key features to look for include protected pressure gauges and auto reciprocating pumps.

- Maintenance and safety are crucial for longevity and safe operation.

- Choosing reputable brands ensures quality and reliability.

Equip yourself with knowledge and the right tools to make your construction projects a success!

Comments

How Injection Packers Enhance the Dam Structures Impermeability

Keeping a dam waterproof is essential for maintaining its structural integrity and preventing water erosion.

Are There Different Size Grease Couplers? A Guide to Finding the Right Fit for Your Equipment

Grease couplers are essential tools in maintaining machinery and crack injection, ensuring that lubrication reaches all the critical parts that keep equipment running smoothly.

Injection Lances for Soil Stabilization: A Technical Overview

Injection lances are essential tools for soil stabilization and ground reinforcement, designed to improve the structural integrity of the soil by injecting stabilizing agents at precise depths.

What Is Injection Packer

Injection packers are vital tools in both construction and maintenance sectors, designed to address critical issues related to sealing and waterproofing.

A Complete Guide to Chemical Injection Lances for Deep Grouting

Chemical injection lances, also known as grout injection lances, are an advanced solution for deep chemical grouting applications.

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

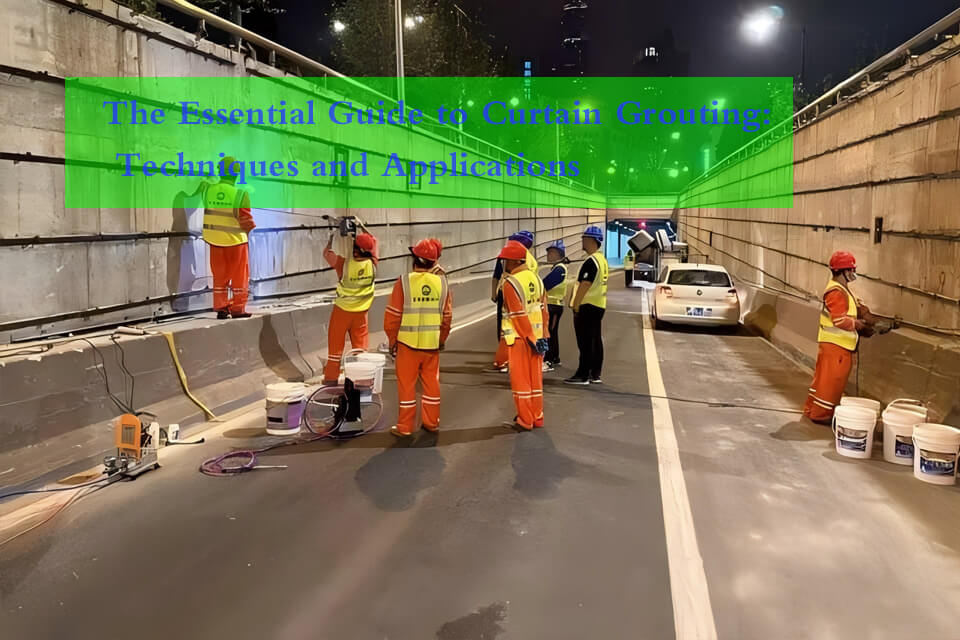

The Essential Guide to Curtain Grouting: Techniques and Applications

Curtain grouting is a revolutionary technique in the construction industry, particularly vital for preventing leaks and reinforcing structures.

Polyurethane Foam Injection: The Ultimate Guide to Foundation Crack Repair

Are you dealing with pesky foundation cracks that just won’t go away? Look no further! This comprehensive guide will walk you through the innovative solution of polyurethane foam injection for crack repair.

What is the Difference Between a Grease Fitting and a Grease Zerk?

If you’re in the world of machinery maintenance, you’ve likely come across the terms “grease fitting” and “grease zerk.”