What is the Difference Between a Grease Fitting and a Grease Zerk?

Table of Contents

What is the Difference Between a Grease Fitting and a Grease Zerk?

Both play crucial roles in keeping equipment running smoothly, but what’s the actual difference between them? In this article, we’ll break down the functions, types, and benefits of grease fittings and zerks, explore when each should be used, and provide practical tips on their maintenance and selection. This guide will be invaluable for anyone looking to optimize their lubrication process, prevent equipment breakdowns, and ensure the longevity of machinery.

Introduction to Grease Fittings and Zerks

Grease fittings, also known as “zerk fittings,” are vital in heavy equipment maintenance, allowing for direct injection of grease into specific machine parts. Despite the interchangeable use of these terms, grease fittings and zerks can refer to slightly different applications depending on context and region.

What Exactly is a Grease Zerk?

A grease zerk is a type of fitting designed with a unique ball check mechanism that opens to allow grease in but closes to prevent contaminants from entering. This one-way valve is particularly effective at delivering grease to bearings, hinges, fifth wheels, and other critical machinery parts that need consistent lubrication. Zerk fittings are known for their durability and ease of use.

Feature | Description |

Mechanism | Ball check valve that opens with pressure |

Common Use | Bearings, joints, high-contact surfaces |

Benefits | Prevents dirt and debris from contaminating lubricated parts |

Sizes | Available in various metric and SAE standards |

Understanding Standard Grease Fittings

While all zerks are grease fittings, not all grease fittings are zerks. Standard grease fittings can include push-in or press-on types that serve similar functions but may lack the ball check valve characteristic of zerks. These fittings allow for grease to be added but may vary in shape, size, and design depending on the machinery.

Type | Features | Common Applications |

Push-in Fitting | Fits with pressure | Light machinery, automotive joints |

Press-on Fitting | Snaps into place | Bikes, small engines, minimal usage |

Zerk Fitting | Threaded or press-fit with valve | Heavy machinery, industrial equipment |

Grease Zerks vs. Grease Fittings: Key Differences

Both grease fittings and grease zerks serve similar purposes but differ slightly in design and application adaptability.

- Grease Zerks: Feature a check valve, ideal for industrial use due to their dirt-prevention capabilities.

- Standard Grease Fittings: Come in multiple forms, with or without a check valve, providing more flexibility for different types of machinery.

Did you know? Zerk fittings are named after Oscar U. Zerk, the inventor, who patented them in the early 20th century for enhanced machinery lubrication.

How to Choose the Right Grease Fitting or Zerk for Your Machinery

Choosing the right grease fitting is crucial for optimal lubrication and longevity of equipment. Consider the following when selecting a fitting:

- Machine Requirements: Check if your machine requires metric or SAE fittings.

- Lubrication Needs: Heavy-duty equipment may need zerks due to their dirt-blocking valve.

- Fitting Size: Matching fitting size is key to ensuring a proper fit and function.

Criteria | Recommended Type |

High-Contact Surfaces | Zerk Fittings |

Light Machinery | Standard Grease Fittings |

Heavy-Duty Equipment | Zerks with high-pressure ratings |

Metric vs. SAE Fittings: How to Tell the Difference

In the United States, grease fittings are often standardized as SAE (Society of Automotive Engineers), while metric fittings are more common in European and Asian machinery. Understanding the difference is essential for maintenance and repair compatibility.

- Metric Fittings: Measured in millimeters (e.g., M6, M8).

- SAE Fittings: Measured in inches (e.g., 1/4″, 1/8″).

Pro Tip: Always double-check the manufacturer’s specifications for recommended fitting sizes and thread standards.

Safety Tips for Using Grease Fittings and Zerks

Safety is paramount when working with grease fittings and zerks, especially when using high-pressure grease guns.

- Wear Protective Gear: Gloves and eye protection are essential when dealing with grease to avoid contamination.

- Secure the Fitting: Ensure the grease fitting is fully engaged with the coupler to prevent leakage.

- Check Pressure Ratings: Exceeding the recommended pressure can cause fittings to burst or detach unexpectedly.

“Always remember to depressurize your grease gun after use to maintain its longevity and avoid accidental discharge.”

Common Applications for Grease Zerks and Fittings

Grease zerks and fittings are used across multiple industries, including:

- Automotive: For lubrication of suspension components, joints, and wheel bearings.

- Industrial Machinery: In high-stress areas like fifth wheels, bearings, and hinges.

- Agricultural Equipment: For maintaining heavy-use parts such as axles, gears, and PTO shafts.

Maintaining Your Grease Zerks and Fittings

Proper maintenance of your grease fittings will extend their lifespan and ensure reliable lubrication.

- Regular Inspection: Check fittings for blockages or wear every 3-6 months.

- Use the Right Grease: Avoid mixing grease types to prevent chemical breakdown.

- Clean Before Application: Always wipe off the fitting before greasing to keep out dirt and debris.

Maintenance Task | Frequency |

Inspect for Blockages | Every 3-6 months |

Clean Fitting Before Use | Every Use |

Lubricate Parts | As Needed |

FAQs on Grease Zerks and Fittings

Can I use a zerk fitting in place of a standard grease fitting?

Yes, zerks are a type of grease fitting and can replace standard fittings where appropriate. However, verify compatibility with your machine.

What type of grease should I use with zerks?

Use grease specified by your machinery’s manufacturer. For heavy-duty equipment, high-viscosity grease is often preferred.

How do I know if my fitting is metric or SAE?

Check the fitting size and markings. Metric fittings are in millimeters (M6, M8), while SAE uses inches (1/8″, 1/4″).

Summary of Key Points

- Grease zerks and standard grease fittings serve similar functions but have distinct design features.

- Metric and SAE fittings differ in size standards; always check compatibility with your equipment.

- Safety is key when using high-pressure grease guns; always wear protective gear and check fitting integrity.

- Regular maintenance and proper grease selection will prolong the life of your fittings and machinery.

Grease fittings and zerks play a crucial role in the health and longevity of industrial and mechanical equipment. Knowing the differences, uses, and maintenance steps for each fitting type can help ensure your machinery operates efficiently for years to come.

Comments

How to Fix Foundation Cracks: Comprehensive Guide to Repairing Cracks in Your Concrete Foundation

Foundation cracks can be an alarming sight, but understanding how to address them can save you time, money, and worry.

The Role of Injection Packers in Crack Injection and Structural Repair

Crack injection is a critical method used in the restoration and strengthening of concrete structures. It involves injecting an adhesive chemical grout or resin into the cracks of a foundation, slab, or wall to seal and restore structural integrity.

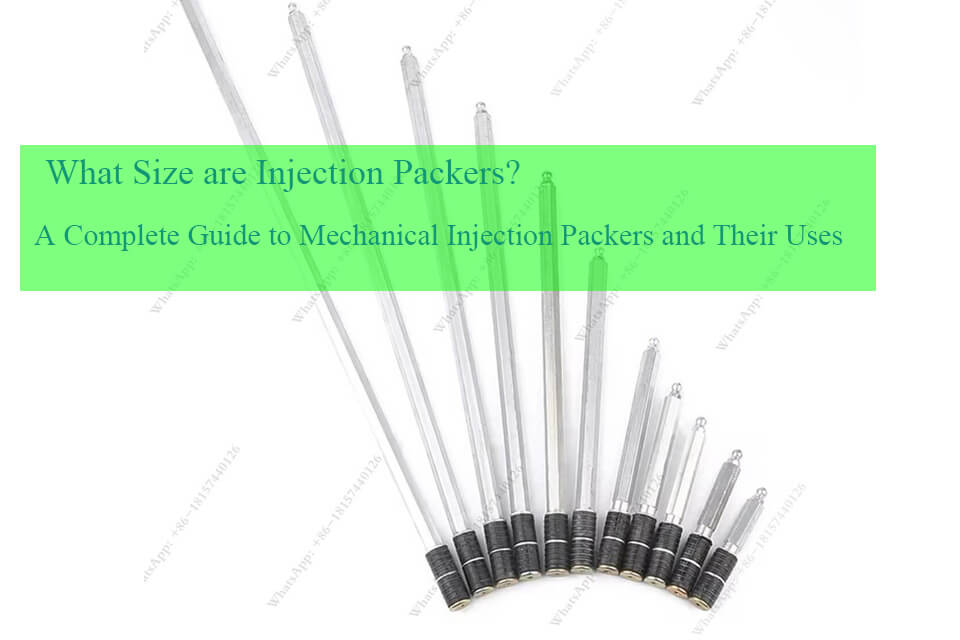

What Size are Injection Packers? A Complete Guide to Mechanical Injection Packers and Their Uses

When it comes to crack injection and waterproofing, the size and type of mechanical injection packers you use can make all the difference.

Unveiling the Power of Heavy-Duty Electric Grout Pumps: Your Ultimate Guide

Have you ever wondered how large structures stay solid and intact? Grouting plays a key role!

What is the Injection Grouting Procedure? A Detailed Guide to Concrete and Masonry Repairs

Injection grouting is a crucial technique used in construction and maintenance for repairing and reinforcing concrete and masonry structures.

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

How to Measure a Button Head Grease Fitting: A Complete Guide

Button head grease fittings are widely used in heavy machinery and industrial applications, ensuring that grease is delivered effectively to vital components.

Key Benefits of Using Injection Packers for Concrete Repair

Injection packers are an essential tool for addressing cracks and structural deficiencies in concrete. These devices allow for precise application of repair materials

Unleashing the Power of Portable Grout Pumps: Your Guide to Compact Grouting Machines

Looking to tackle a construction project that involves grouting but worried about heavy equipment? Discover how portable grout pumps can revolutionize your work!