Understanding Grouting Packers: Essential Tools for Effective Injection Grouting

Table of Contents

What is a Packer in Grouting

Mechanical packers and inflatable grout packers offer different solutions for sealing and stabilizing structures, ensuring strong, durable, and effective repairs. This article delves into what grouting packers are, their types, applications, and why they’re indispensable tools for construction and repair projects.

Whether you’re new to injection grouting or looking to refine your understanding of grout packers, this article provides an in-depth look at these tools and their role in seal repair, crack sealing, and soil stabilization. Learn about the benefits of different packer types, common applications, and how to select the best option for your project.

What Is a Grouting Packer?

A grouting packer is a specialized tool used in injection grouting to help inject materials like epoxy or chemical grout into concrete or soil. Packers are placed into pre-drilled holes where they form a tight seal, allowing grout to flow into targeted cracks or voids without leaking.

Typically made of metal or rubber, mechanical and inflatable grout packers offer distinct advantages depending on the application. They are essential for soil stabilization, leak sealing, and crack repair in various structures.

Why Are Packers Essential for Injection Grouting?

Packers enable precise grouting by directing material flow into specific areas. Without a packer, grout could seep uncontrollably, reducing the efficacy of the seal and wasting material.

Injection packers are vital in:

- Waterproofing: Preventing leaks in walls, foundations, and tunnels.

- Structural Integrity: Filling cracks and voids to restore structural strength.

- Soil Stabilization: Injecting grout into soil to prevent settling or shifting.

Using the correct packer can significantly enhance the durability and effectiveness of a grouting project.

Types of Grouting Packers: Mechanical vs. Inflatable

Grouting packers come in two main types: mechanical and inflatable. Here’s a comparison to help you choose the best type for your project:

- Mechanical Packers: Made with metal components and fitted with rubber seals, these packers are ideal for high-pressure injection jobs. They are sturdy and commonly used for concrete crack repair.

- Inflatable Grout Packers: These packers expand to create a tight seal within the hole. Ideal for softer materials like soil, inflatable packers are well-suited for soil stabilizationprojects or applications in irregularly shaped spaces.

Each packer type has its strengths, making it essential to assess the requirements of your grouting solution before selecting one.

How Do Injection Packers Work?

Injection packers work by creating a seal within a drilled hole, allowing for controlled injection of grout. Here’s how the process works in three main steps:

- Installation: The packer is inserted into the drilled hole and tightened to form a secure seal.

- Injection: Grout is injected through the packer into the crack or void.

- Sealing and Hardening: The grout fills the target area, then hardens to form a permanent seal.

By maintaining pressure during grout injection, packers ensure that the material reaches the desired location, preventing leakage and maximizing effectiveness.

Key Components of a Grout Packer System

A packer system consists of various components, each contributing to the success of the grouting process:

- Body: The main part of the packer that fits into the hole.

- Seals: Rubber or expandable parts that ensure a tight fit.

- Valve: Controls the flow of grout into the crack or void.

- Injection Port: Where grout material enters the packer for delivery.

Understanding these components helps ensure you choose and use packers effectively for sealing and stabilization.

When to Use Mechanical Packers for Grouting?

Mechanical packers are best suited for high-pressure applications and rigid materials like concrete. They are commonly used in foundation crack repair and structural grouting where the material requires a solid, non-expanding seal.

In injection grouting, mechanical packers offer reliable results due to their durability and ability to withstand pressure. They’re also reusable, making them an economical choice for frequent projects.

Advantages of Inflatable Grout Packers

Inflatable packers are ideal for applications where variable hole sizes or softer materials, such as soil, are involved. Here are some advantages:

- Flexibility: Inflate to fit irregular shapes and sizes.

- Soft Material Compatibility: Work well with materials like soil, minimizing disturbances.

- Effective Void Filling: Adaptable to fill varying cavity sizes.

Their ability to conform to different shapes and sizes makes inflatable packers a versatile option in soil stabilization and void filling applications.

How to Choose the Right Packer for Your Project

Choosing the correct packer type depends on several factors:

- Material of Structure: Concrete, soil, or rock.

- Pressure Requirements: High-pressure vs. low-pressure injection.

- Size of Cracks or Voids: Large voids may require inflatable packers.

- Budget and Reusability: Mechanical packers are more durable and reusable.

Consider consulting a grouting expert if you’re unsure about the ideal packer type for your project. Selecting the wrong packer could lead to wasted grout or ineffective sealing.

Proper Maintenance for Long-Lasting Packers

Proper maintenance ensures grouting packers remain functional and extend their lifespan. Here are tips for packer upkeep:

- Clean After Each Use: Remove grout residue to prevent clogging.

- Inspect Seals and Valves: Check for wear to avoid leaks.

- Store Properly: Keep packers in a dry place to prevent rust and material degradation.

By following these steps, you can maximize the durability and efficiency of your injection packer equipment, making each grouting project more cost-effective.

Conclusion

Injection packers are indispensable in injection grouting for both waterproofing and soil stabilization. By ensuring precise, controlled grout placement, they prevent leaks, stabilize structures, and enhance project durability. Whether you’re working on a small repair or a large stabilization project, choosing the right packer type is essential.

Key Takeaways on Grouting Packers

- Definition: Packers are essential tools for injecting grout into cracks and voids.

- Types: Mechanical packers for high-pressure, concrete applications; inflatable packers for flexible, soil-based uses.

- Application: Used in waterproofing, crack repair, soil stabilization, and void filling.

- Selection Tips: Choose based on material, pressure, size, and project requirements.

- Maintenance: Regular cleaning and inspection can extend packer lifespan and maintain effectiveness.

For more information on selecting and using grouting packers effectively, consult a professional injection grouting expert

Comments

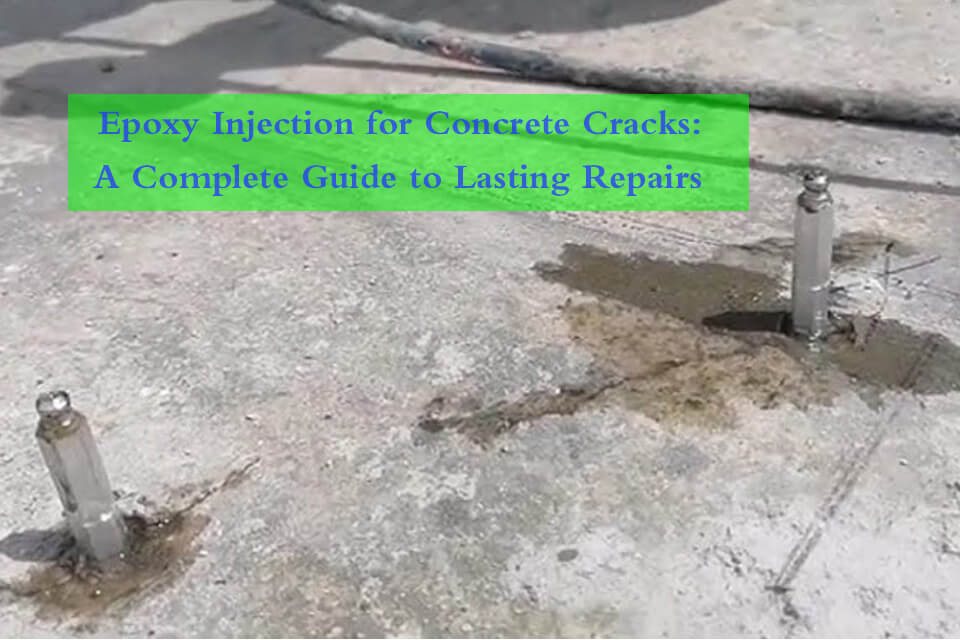

Epoxy Injection for Concrete Cracks: A Complete Guide to Lasting Repairs

In this article, learn how epoxy injection effectively restores structural integrity to cracked concrete, providing a durable, lasting solution.

What Are Grease Fittings Used For?

Grease fittings, also known as zerk fittings, are small but critical components in the world of machinery maintenance and waterproof industry.

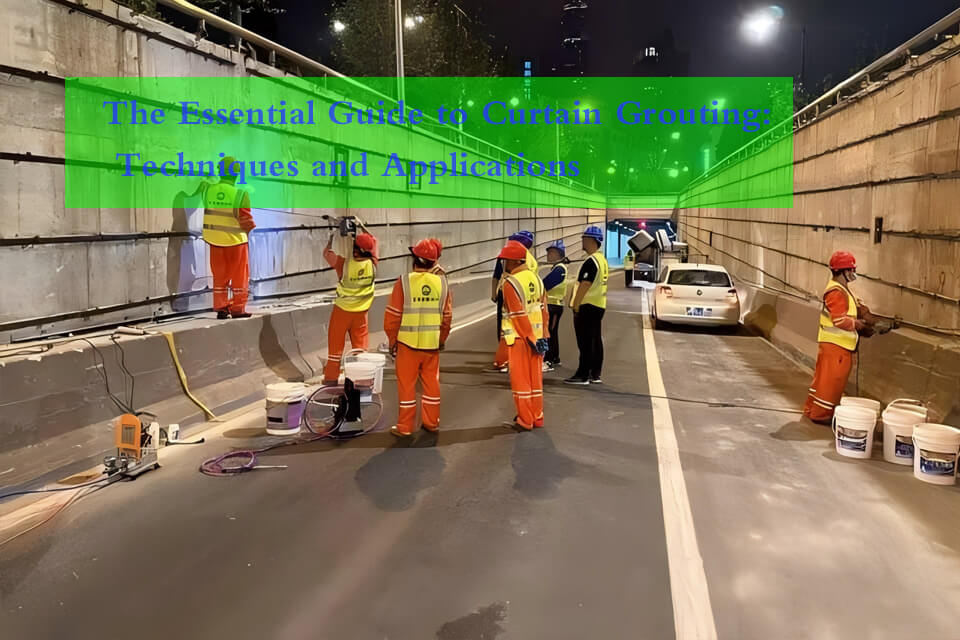

The Essential Guide to Curtain Grouting: Techniques and Applications

Curtain grouting is a revolutionary technique in the construction industry, particularly vital for preventing leaks and reinforcing structures.

Polyurethane Foam Injection: The Ultimate Guide to Foundation Crack Repair

Are you dealing with pesky foundation cracks that just won’t go away? Look no further! This comprehensive guide will walk you through the innovative solution of polyurethane foam injection for crack repair.

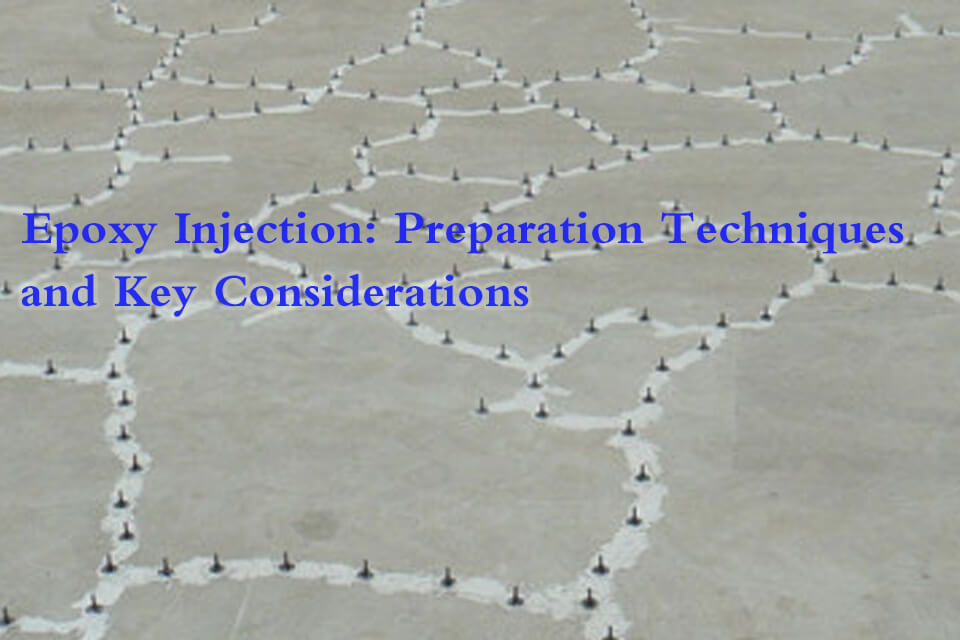

Epoxy Injection: Preparation Techniques and Key Considerations

Epoxy injection is a sophisticated technique employed in the restoration of concrete structures by delivering a high-strength, low-viscosity epoxy resin into cracks.

- [email protected]

- +86 18157440126

- Mon-Sun 8:00-21:00

Tags

Chemical Grouting for Soil Stabilization: A Complete Guide to the Process and Benefits

Chemical grouting is an effective method for soil stabilization and strengthening structures in construction and civil engineering.

Polymer Soil Stabilization: The Key to Sustainable Ground Solutions

Soil stabilization is vital in construction and civil engineering, particularly for enhancing soil properties and ensuring durable infrastructure.

Unleashing the Power of Portable Grout Pumps: Your Guide to Compact Grouting Machines

Looking to tackle a construction project that involves grouting but worried about heavy equipment? Discover how portable grout pumps can revolutionize your work!